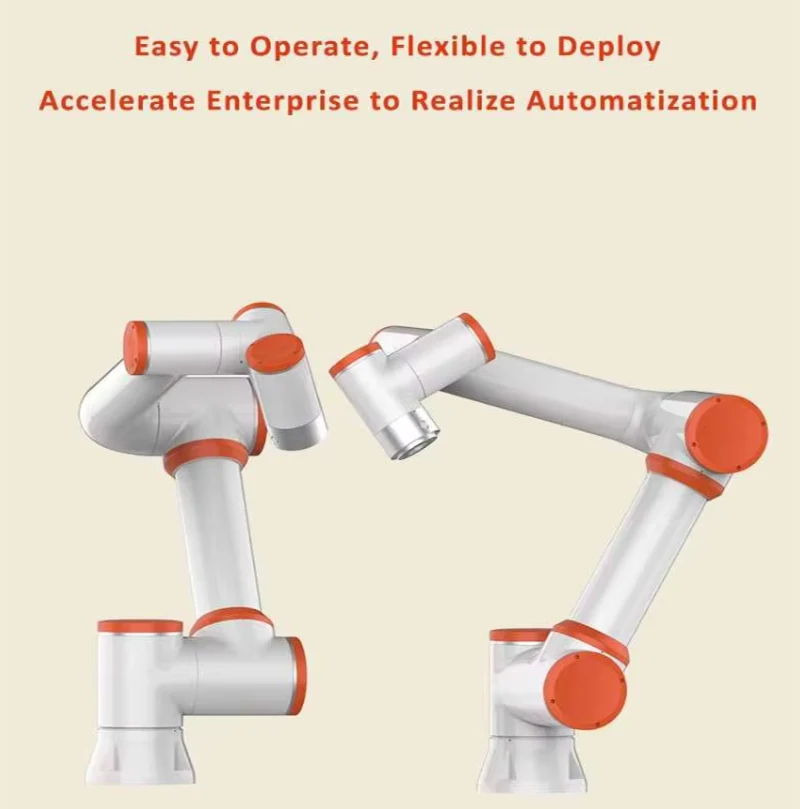

Six-axis intelligent welding collaborative robot: opening a new era of welding

In the field of industrial manufacturing, the accuracy and efficiency of welding processes are crucial to product quality and production benefits. With its advanced technology and excellent performance, the six-axis intelligent welding collaborative robot has become an innovative tool for welding operations.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

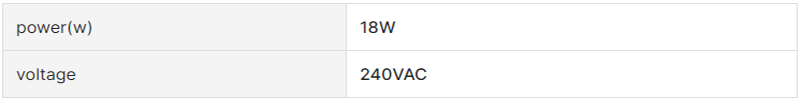

- Feature highlights: This 6-axis collaborative robot arm boasts a 5kg payload capacity and IP54 protection, ensuring reliable performance in industrial environments. Equipped with advanced core components like PLC and motor, it supports automated packaging and logistics applications. The product includes a machinery test report for quality assurance.

Advanced mechanical structure design of the six-axis industrial welding collaborative robot

Flexible six-axis linkage

The robot is equipped with six rotating axes, which can be flexibly linked to achieve 360° all-round spatial movement. This enables it to easily cope with various complex welding angles and trajectories, whether it is welding point connection in a small space or long weld operation of large workpieces, it can be accurate and in place, avoiding welding defects caused by angle restrictions in traditional welding.

High load and stable operation

It has excellent load capacity and can be adapted to a variety of heavy welding equipment, such as high-power welding guns. At the same time, the sturdy mechanical structure design is matched with high-precision transmission components to ensure that the robot is still stable and reliable during high-speed operation and heavy-load operation, effectively reducing vibration and shaking, and ensuring the stability and consistency of the welding process.

Intelligent control system of the six-axis industrial welding collaborative robot

Intelligent programming and teaching

Using an intuitive teaching programming method, the operator can manually guide the robot to complete the welding action through the teach pendant, and the system automatically records the path and parameters to quickly generate the welding program. In addition, it also supports offline programming. With the help of professional software, the welding process can be simulated on the computer, the optimal path can be planned in advance, the on-site debugging time can be greatly shortened, and production efficiency can be improved.

Real-time sensing and adaptive adjustment

Built-in multiple sensors, such as weld tracking sensors, arc sensors, etc. The weld tracking sensor can detect the position and shape of the weld in real time, automatically adjust the robot's running trajectory, and ensure that the welding gun is always aligned with the weld; the arc sensor can adaptively adjust the welding current, voltage and other parameters according to the changes in arc parameters during the welding process, to ensure stable welding quality and adapt to different materials and welding requirements.

Wide range of application fields

Automobile manufacturing industry

It plays a key role in the welding of automobile bodies, and can efficiently complete the welding tasks of doors, frames, chassis and other components. Its high precision and stability ensure the welding quality of the body, improve the overall safety and reliability of the car, and speed up the production rhythm to meet the needs of large-scale automated production of automobiles.

Mechanical equipment manufacturing

It is suitable for welding metal structural parts of various types of mechanical equipment, such as frames of engineering machinery, steel structures of bridges, etc. It can perform high-quality welding on heavy plates, reduce the labor intensity and skill requirements of manual welding, improve welding efficiency and quality, and help the mechanical equipment manufacturing industry upgrade to intelligence and efficiency.

Aerospace field

Meet the stringent requirements of aerospace parts for welding accuracy and quality. It can be used to weld precision parts such as aircraft engine blades and spacecraft structural parts. By accurately controlling welding parameters and processes, it ensures the strength and reliability of welded joints, providing strong support for high-end aerospace manufacturing.

Significant benefit improvement of six-axis industrial welding collaborative robots

Improve production efficiency

Compared with manual welding, six-axis intelligent welding collaborative robots can achieve 24-hour uninterrupted operation, with fast and stable welding speed, which greatly shortens the production cycle. At the same time, the automated welding process reduces the time loss of manual shifts, rest, etc., effectively improving production capacity.

Reducing costs

On the one hand, robot welding reduces the dependence on a large number of highly skilled welders and reduces labor costs; on the other hand, precise welding parameter control reduces welding material waste and improves material utilization. In addition, stable welding quality reduces the defective rate and rework rate, further saving production costs.

Product description

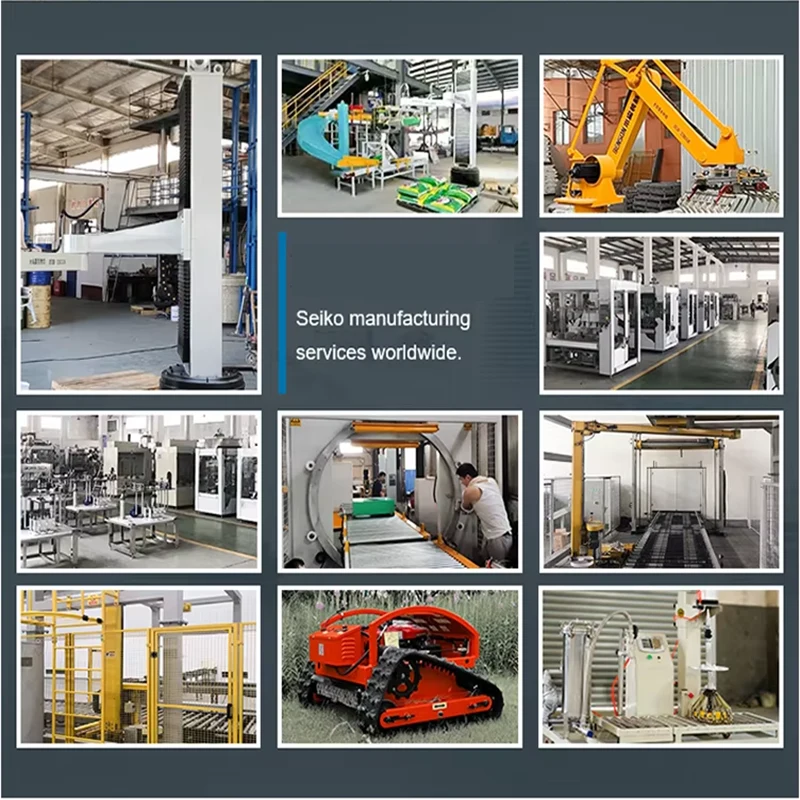

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved the product quality. The products of Bensen (Shandong) Machinery Co., Ltd. have been widely used in other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry