Six-axis loading industrial welding and spraying collaborative robot - the core force of industrial automation

Under the wave of Industry 4.0, the manufacturing industry has an increasingly urgent demand for automation and intelligence. As a representative of advanced manufacturing technology, the six-axis loading industrial welding and spraying collaborative robot is becoming a key equipment for improving production efficiency, ensuring product quality and reducing costs.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

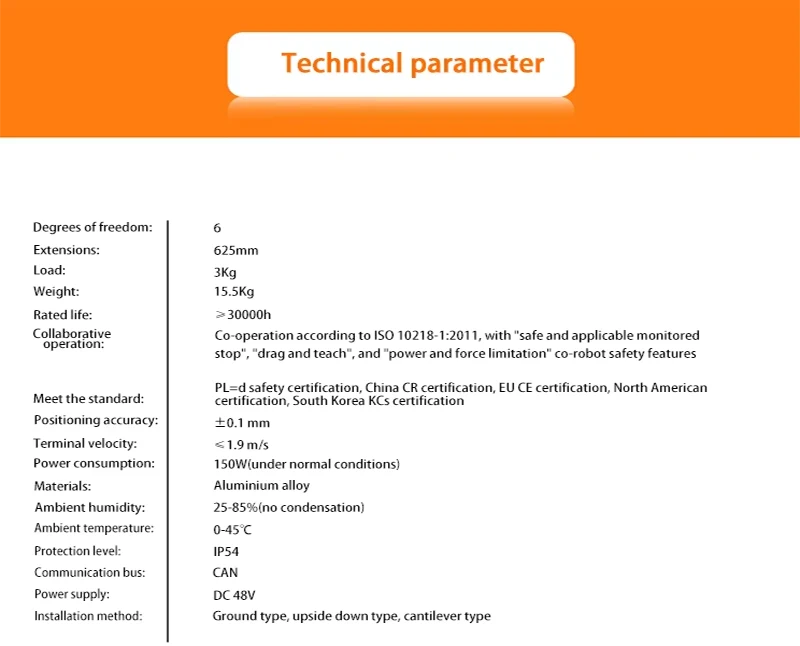

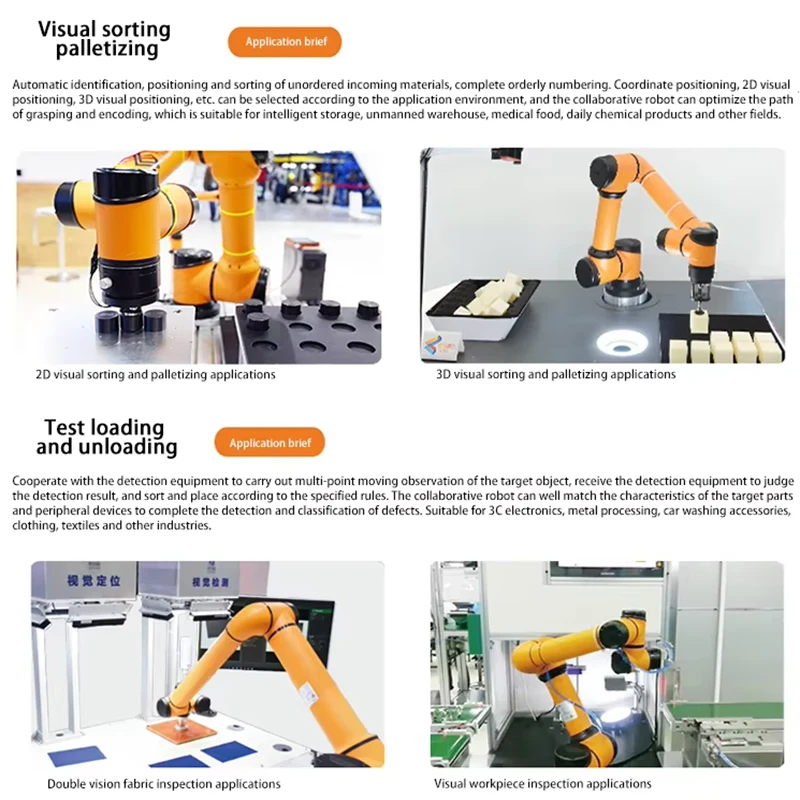

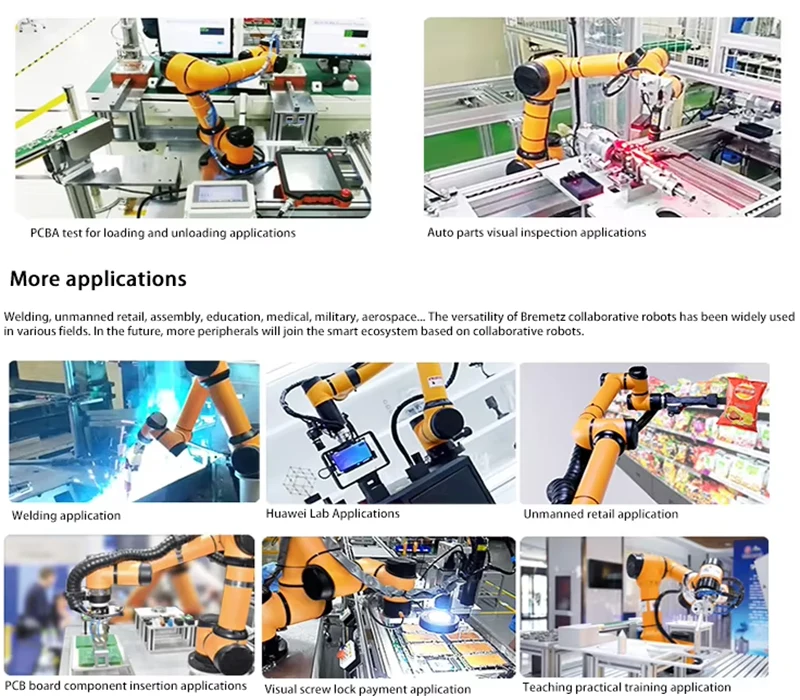

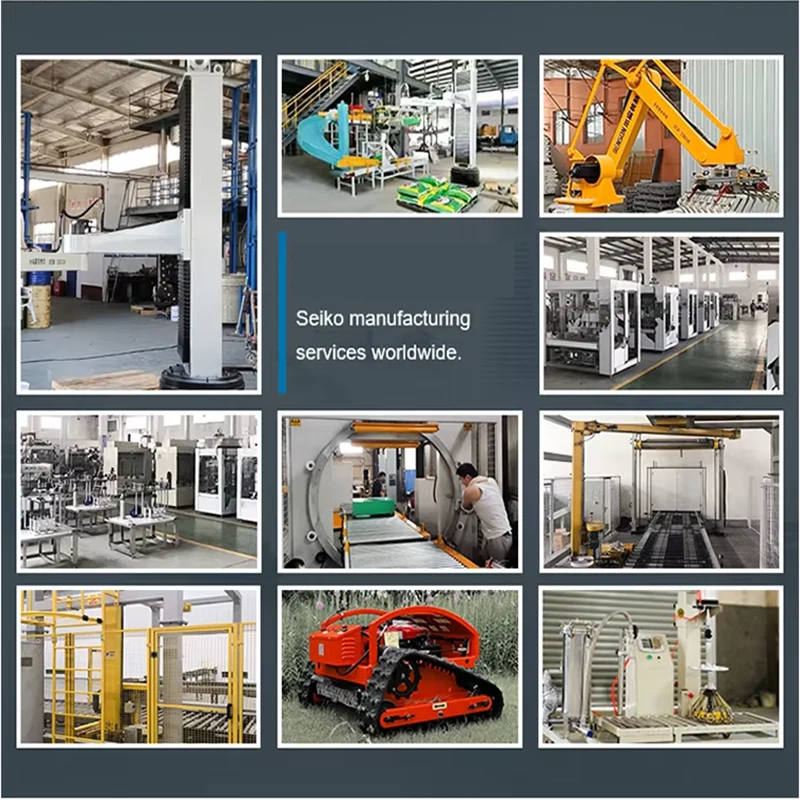

Functional highlights: This six-axis collaborative robot arm supports welding, spraying, cooking, palletizing, picking and loading, with optional load capacities of 5 kg, 10 kg and 20 kg. It is very suitable for automated industrial tasks in the food, beverage, construction and logistics industries. The core components of this product are provided with a one-year warranty, and come with video factory inspection and mechanical test reports to ensure high quality and reliability.

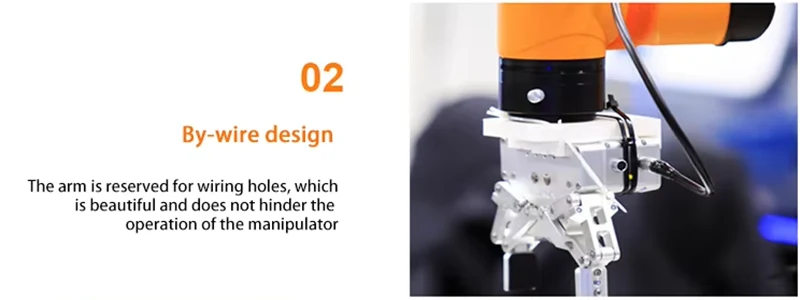

Excellent mechanical design of the six-axis loading welding spraying robot

Six-axis linkage, flexible operation: It has six independently controllable axes and 360° full-range motion capability. Whether it is complex three-dimensional curved surface welding or fine spraying in a small space, it can be easily handled. In the welding of automotive parts, welds of various angles and shapes can be accurately completed; when spraying on the surface of furniture, every corner can be evenly covered to ensure excellent appearance quality.

High load capacity: It is designed with a strong load capacity, which makes it adaptable to large welding equipment and efficiently complete the welding tasks of heavy workpieces; in the spraying operation, it can also stably carry various types of spray guns to achieve continuous and efficient spraying work.

Advanced control system of the six-axis loading welding spraying robot

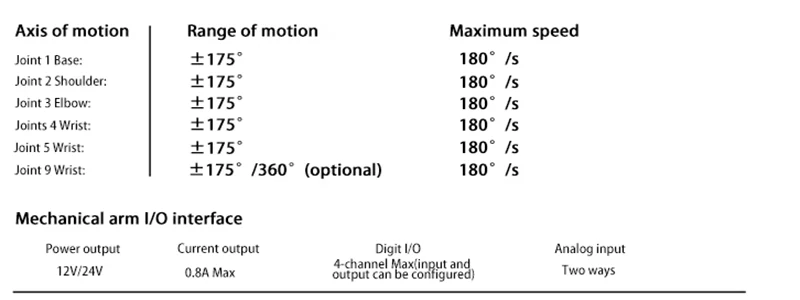

Intelligent programming and teaching: Equipped with an intuitive teaching pendant, the operator can record the action by manually dragging the robot arm and quickly complete the programming. It also supports offline programming, using professional software to simulate the robot's motion trajectory on the computer, and then transmit the generated program to the robot, which greatly saves on-site debugging time and improves production preparation efficiency.

Precise motion control: Using advanced motion control algorithms to ensure that the robot maintains high precision during high-speed motion. Ensure the position consistency of each welding and spraying, effectively improve the stability of product quality, and reduce the defective rate.

Wide application fields of six-axis loading welding and spraying robots

Automobile manufacturing: On the automobile body welding line, it undertakes welding work of various key parts, such as doors, frames, etc., to ensure the strength and safety of the body structure. In the spraying link of automobile parts, it can accurately control the spray gun to achieve a uniform and beautiful paint effect and improve the appearance quality of the car.

Metal processing: Suitable for welding and surface treatment of various metal products, such as steel structures, pipes, mechanical parts, etc. Whether it is carbon steel, stainless steel or aluminum alloy, it can show excellent welding and spraying performance to meet the process requirements of different metal materials.

Furniture manufacturing: In furniture production, complete the welding of metal connectors of wooden furniture, as well as painting, powder spraying and other coating operations on the surface of furniture. Its high precision and flexibility can realize the spraying of complex patterns and textures, adding unique artistic charm to furniture.

Significant economic benefits of six-axis loading welding spraying robot

Improve production efficiency: Compared with manual operation, the robot can work 24 hours a day, greatly shortening the production cycle. Taking welding operation as an example, it can greatly increase production capacity and meet the needs of large-scale production.

Reduce costs: Reduce dependence on a large number of manual labor, reduce labor costs and management costs. At the same time, precise operation can reduce the waste of raw materials. For example, during the spraying process, the amount of paint can be accurately controlled, reducing paint loss, and further saving production costs.

Product Description

Company Profile

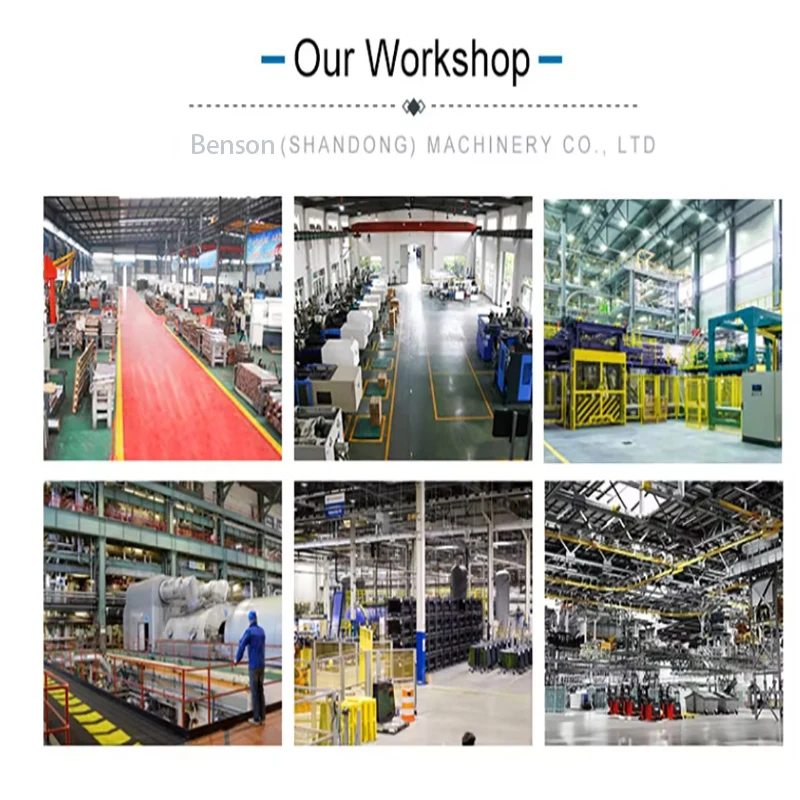

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research", and the success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been used, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in machinery manufacturing, automation equipment manufacturing, automated production lines, automated production lines, etc. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

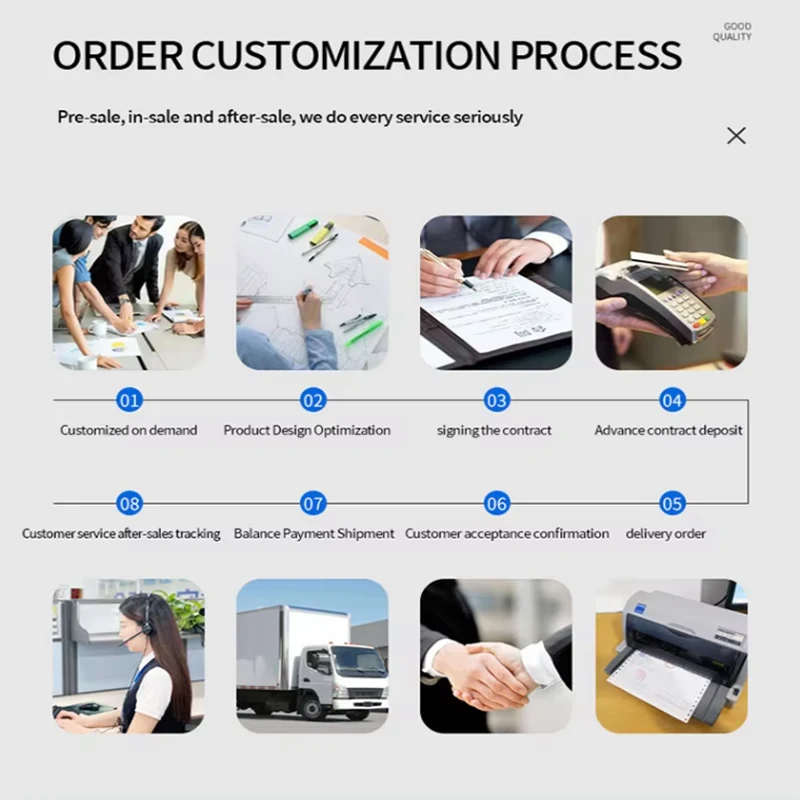

Product Inquiry