30kg load pallet transporter collaborative robot operates stably under high load

Adopting high-strength lightweight aluminum alloy body and optimized six-axis mechanical structure, with high-precision harmonic reducer and servo motor, it can still maintain stable movement under 30kg full load conditions, avoiding material shaking and falling risks, and is suitable for handling scenarios such as heavy pallets and large equipment parts.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Core technical advantages of the six-axis pallet transporter collaborative robot

Human-machine collaborative safety design

Equipped with contact force sensors and non-contact infrared sensing devices, the robot will immediately slow down or stop when a human body approaches or collides with it. It supports manual traction teaching function to achieve safe and efficient human-machine collaborative operation.

Multi-mode flexible adaptation

- Manual mode: Precisely control the action through the teach pendant or tablet terminal;

- Automatic mode: Connect to the MES/WMS system, and automatically complete the pallet pick-up and transportation after receiving the task instructions;

- Cluster scheduling: Support multiple robots to work together, and realize task allocation and scheduling optimization through the central management system.

Configuration and scalability of the six-axis pallet transporter collaborative robot

Hardware configuration

- Body: Modular design, easy to maintain and upgrade;

- End effector: Standard quick-change interface, supports a variety of pallet grabbing tools such as suction cup and gripper;

- Communication interface: Support Ethernet, Modbus TCP, OPC UA and other protocols, seamlessly connected to the factory automation system.

Six-axis pallet transporter collaborative robot software system

- Self-developed pallet management software, supporting task editing, operation monitoring, and data analysis;

- Provide API interface for easy integration with enterprise ERP, PLC and other systems.

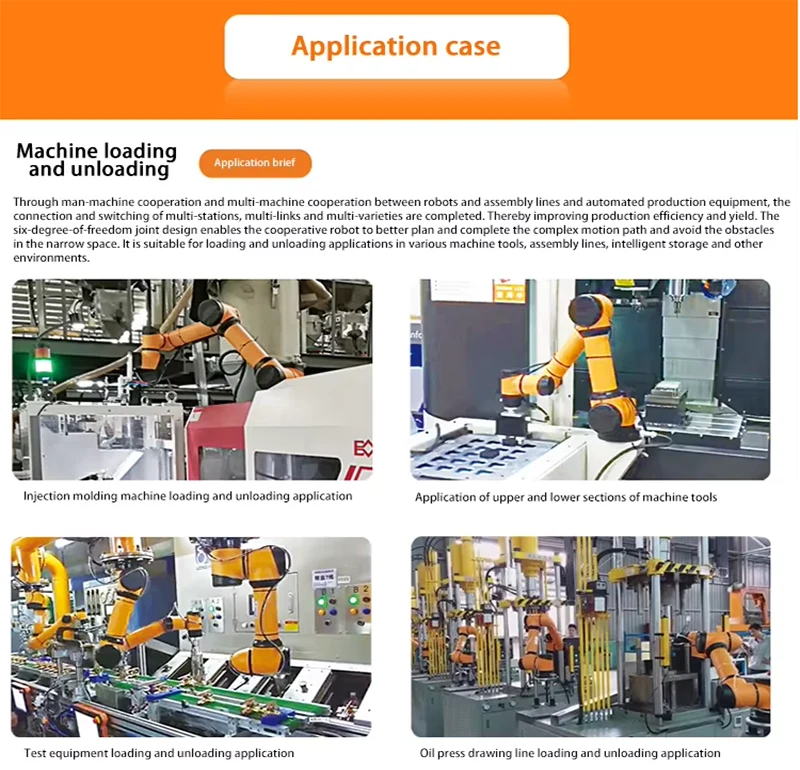

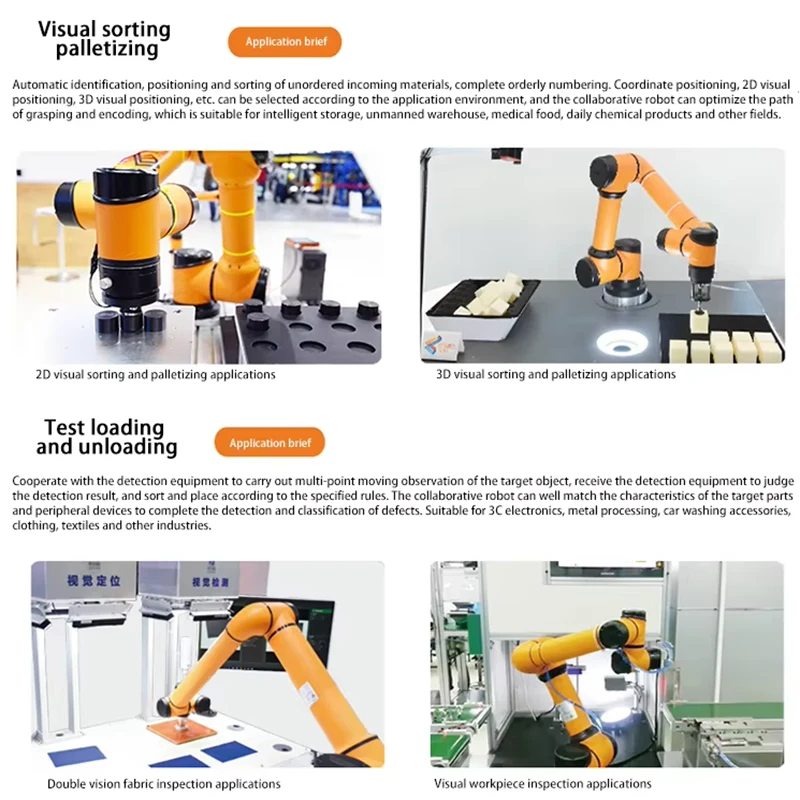

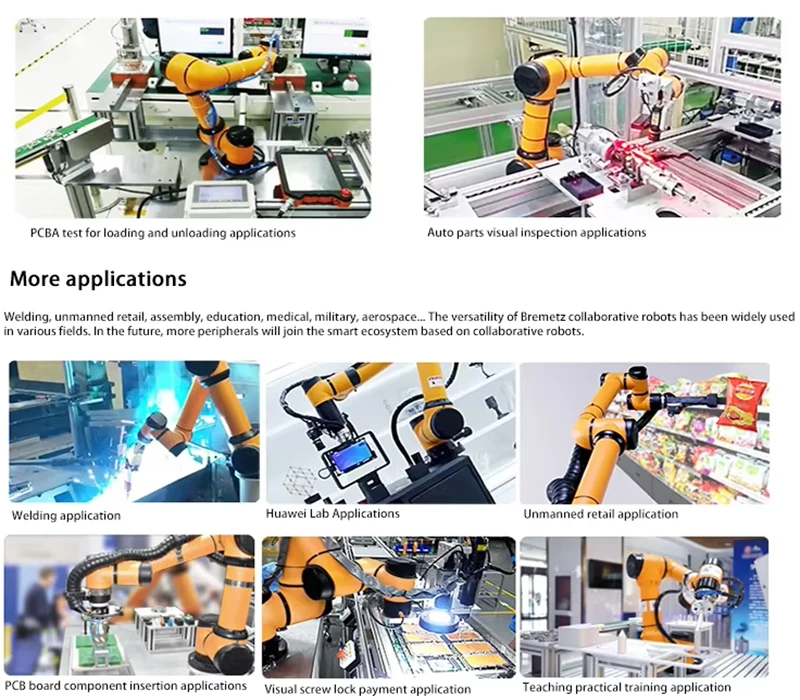

Application scenarios of six-axis pallet transporter collaborative robot

Manufacturing production line: in the automotive, home appliance, mechanical processing and other industries, to achieve efficient transfer of pallet materials between production lines;

Warehousing and logistics: used in stereoscopic warehouses and sorting centers to complete the in-and-out handling and stacking of pallet goods;

E-commerce sorting: cooperate with the automated sorting system to quickly transport parcel pallets and improve sorting efficiency;

Food and medicine: models that meet clean standards, suitable for pallet material transfer in food and drug production workshops.

Product Description

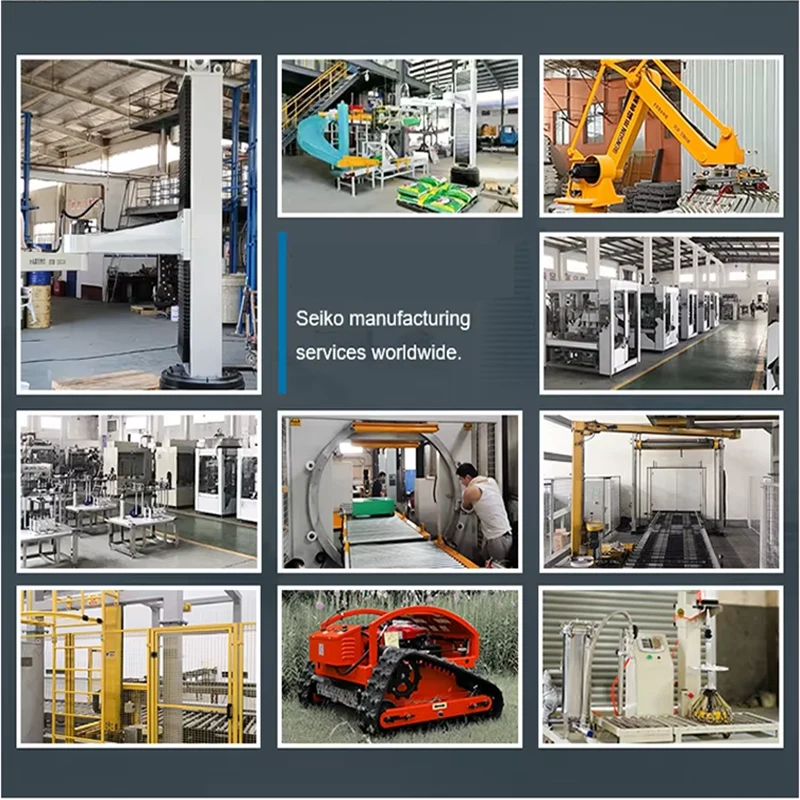

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research", and the success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been used, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in machinery manufacturing, automation equipment manufacturing, automated production lines, automated production lines, etc. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry