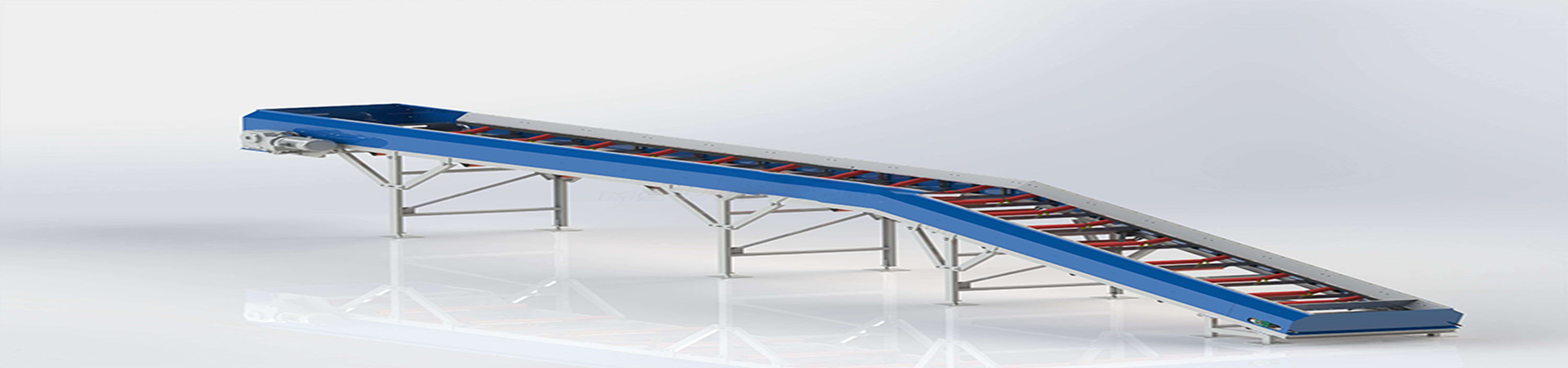

Loading and unloading tie rod roller conveyor: a powerful assistant for efficient logistics

In the field of modern logistics and industrial production, efficient cargo loading and unloading and transportation are essential. As a device designed to solve the problem of logistics handling, the loading and unloading tie rod roller conveyor has become a powerful assistant for many companies to improve efficiency with its many advantages.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

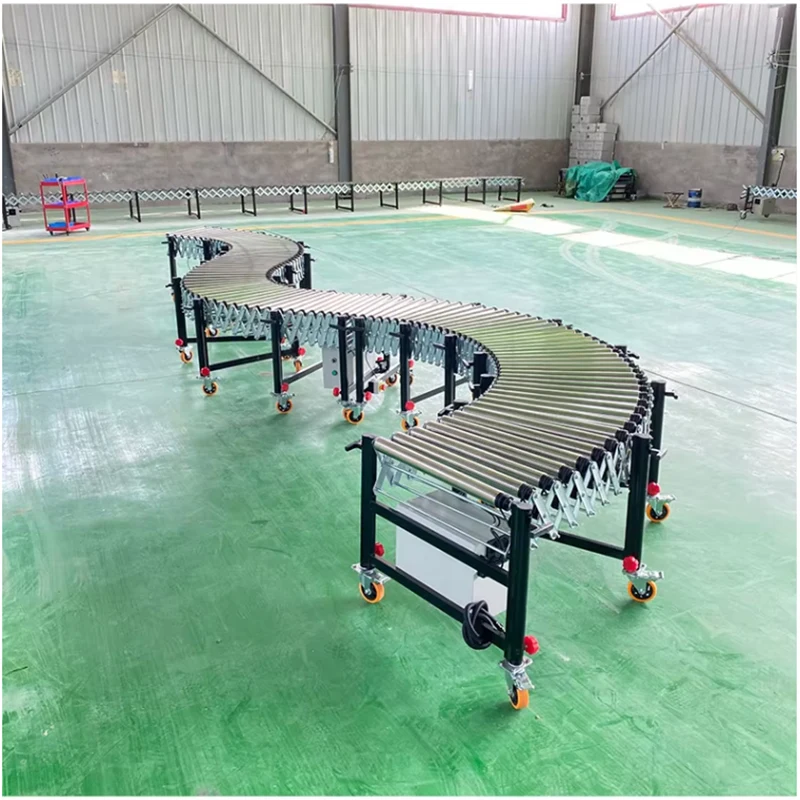

The loading and unloading tie rod roller conveyor is exquisitely designed and flexible

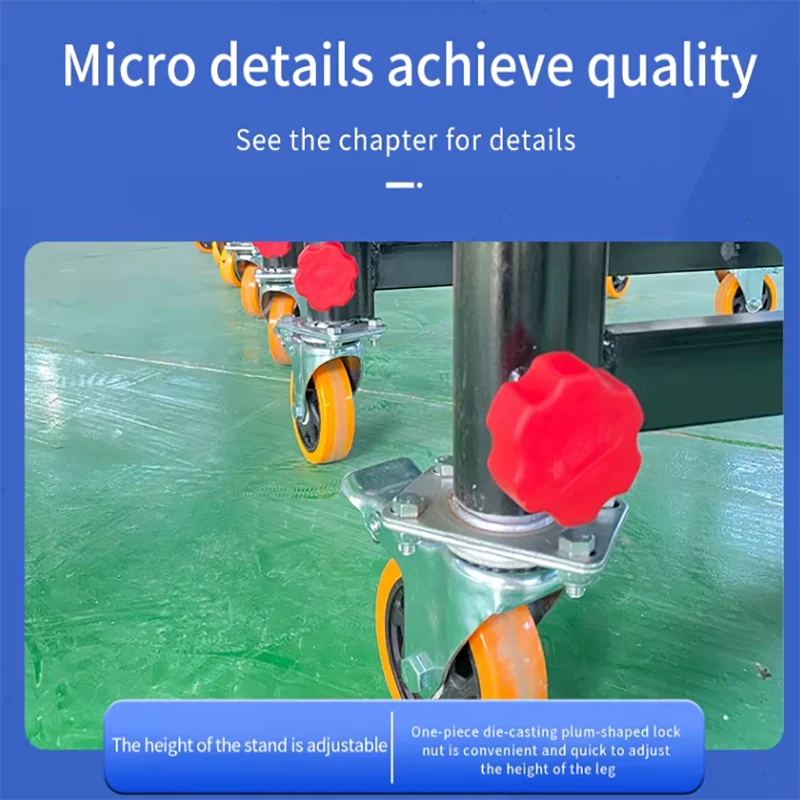

Universal brake casters: The high-quality universal brake casters installed at the bottom not only move smoothly and can adapt to various complex ground surfaces, but also when positioning, you only need to easily step on the brake to keep the equipment stable and ensure safe and stable loading and unloading operations.

Free telescopic function: The conveyor body has excellent telescopic ability. It can freely adjust the conveying length according to the actual operation scene, such as the length of the truck compartment, the distance between the loading and unloading platform and the warehouse, etc., to achieve seamless docking, effectively reduce the cargo handling path, and improve work efficiency.

The loading and unloading tie rod roller conveyor is sturdy and durable, with strong load-bearing capacity

High-strength carbon steel material: The overall frame is carefully made of high-strength carbon steel, and has undergone strict welding process treatment to ensure a stable structure with excellent anti-deformation ability. It can withstand frequent loading and unloading of heavy-loaded goods and can operate stably for a long time in harsh working environments.

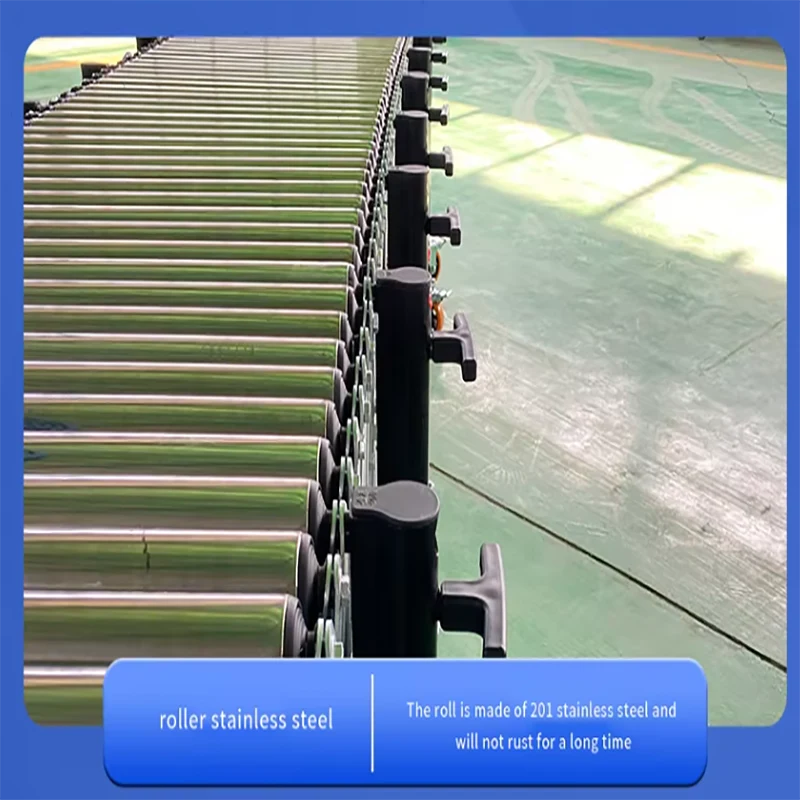

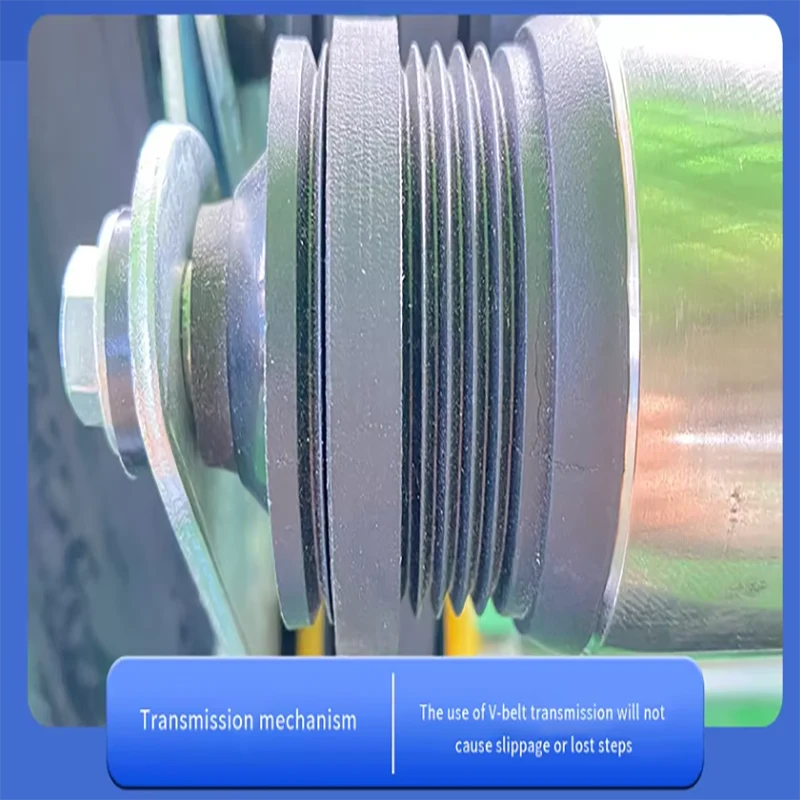

High-quality roller configuration: The high-quality rollers used have special wear-resistant, anti-slip and corrosion-resistant treatments on the surface, which effectively increase the friction between the goods and ensure that the goods move smoothly during transportation; the roller spacing is scientifically designed to carry goods of various specifications, with strong conveying capacity, which can meet the needs of long-term continuous operation.

The height of the loading and unloading tie rod roller conveyor is adjustable and widely adaptable

The legs adopt a humanized lifting design with a large height adjustment range. They can easily adapt to truck compartments, warehouse shelves, etc. of different heights to meet diverse loading and unloading needs, ensure smooth loading and unloading of goods, and avoid damage to goods due to height differences.

The loading and unloading tie rod roller conveyor is easy to operate and safe

Easy to operate: The operation of the conveyor is extremely simple and does not require professional skills training. The staff can master it in a short time, reducing the difficulty of manual operation and improving work efficiency.

Multiple safety protections: Equipped with an emergency brake device, in an emergency, the operator can quickly press the button to stop the equipment immediately to avoid accidents; at the same time, there are safety facilities such as guardrails to effectively prevent goods from slipping and fully protect the personal safety of operators.

Wide application and significant value

Logistics warehousing: In logistics warehouses, it is used for rapid loading and unloading of goods, and can efficiently transfer goods from trucks to warehouse shelves, or from shelves to trucks, greatly improving the turnover efficiency of warehousing logistics.

Express sorting: Express outlets use loading and unloading pull rod roller conveyors, which can cooperate with automated sorting systems to quickly complete the loading and unloading and sorting of packages, and easily cope with the massive package processing tasks during the express peak period.

E-commerce distribution: When e-commerce warehouses ship goods, with the help of this equipment, the packaged goods can be conveniently transported directly to the transport vehicles, significantly improving the delivery efficiency and ensuring that the orders can be delivered to customers in time.

Factory workshop: Inside the factory, the production line and the truck are connected to realize the rapid unloading of raw materials and the loading and delivery of finished products, optimize the internal logistics process of the factory, and ensure the continuity of production.

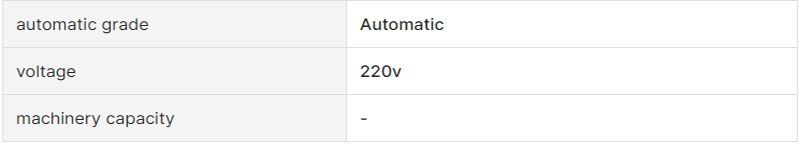

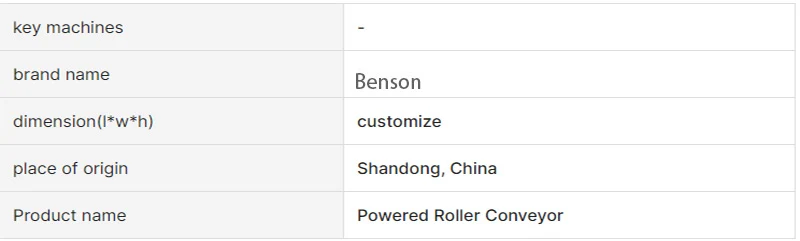

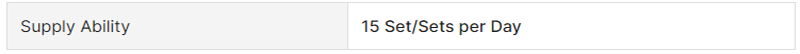

Products Description

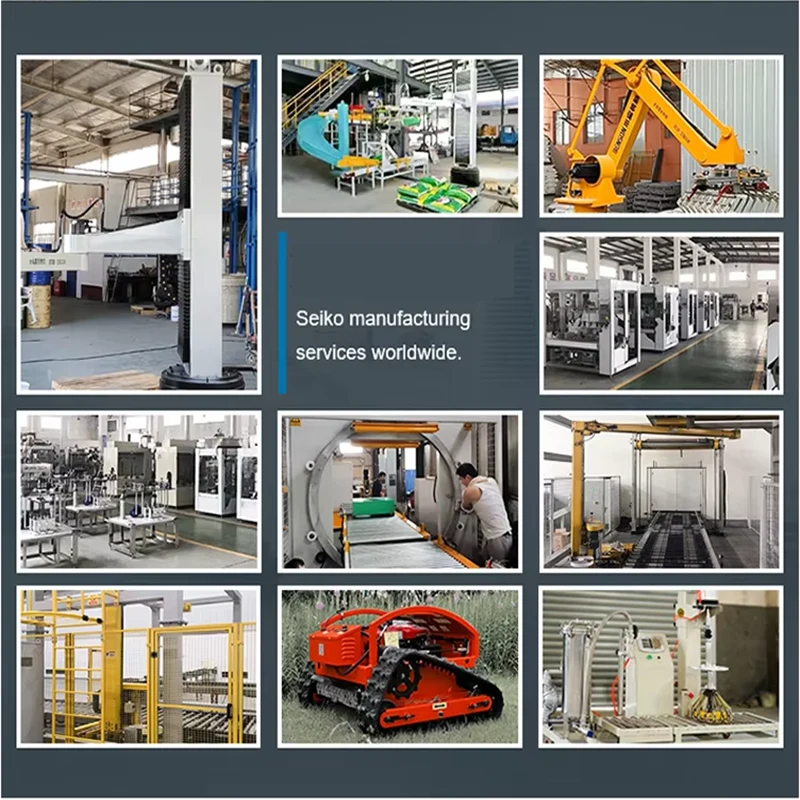

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry