The small bag filling machine for instant coffee powder is an automated packaging device specifically designed for instant coffee powder. It can accurately fill a fixed quantity of coffee powder into small-sized packaging bags. This equipment integrates core functions such as feeding, metering, filling, and sealing, and can achieve one-stop operation from raw materials to finished product packaging. It is widely applied in the food processing industry, especially in coffee production enterprises

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Small bag filling machine for instant coffee powderAdvantages

1. High efficiency and precision: It adopts a high-precision metering system to ensure that the weight error of each bag of coffee powder is extremely small. With a fast filling speed, it can greatly improve production efficiency and meet the requirements of large-scale production.

2. Multifunctionality: It is compatible with small bag packaging of different weights and specifications. Whether it is a 2-gram portable package or a 10-gram family package, it can handle it easily. It can also be adapted to various sealing forms such as three-side sealing and four-side sealing.

3. Automated operation: The equipment has a high degree of automation. From the conveying of coffee powder, filling to sealing and counting, it requires little manual intervention, reducing labor costs and at the same time minimizing human operation errors.

4. Hygiene and safety: The parts of the equipment that come into contact with coffee powder are made of food-grade stainless steel, which is easy to clean and corrosion-resistant, meeting food hygiene standards and ensuring product safety.

5. Stable and reliable: After strict quality inspection and performance testing, the mechanical structure is sturdy and durable, with stable operation and a low failure rate. It can work continuously for a long time, reducing downtime for maintenance.

Small bag filling machine for instant coffee powderApplications

1. Coffee production enterprises: Suitable for large coffee manufacturing enterprises and small and medium-sized coffee processing plants, used for the small bag packaging of products such as instant black coffee and three-in-one instant coffee.

2. Beverage OEM enterprises: Provide small bag filling OEM services for brand owners for instant coffee powder, meeting diverse product customization needs.

3. Hotels and the catering industry: Fill small bags of coffee powder, which are used for coffee packets in hotel rooms and self-service coffee stations in restaurants, providing customers with a convenient coffee drinking experience.

4. Retail and e-commerce: Produce small bag instant coffee products suitable for sale on retail shelves and e-commerce platforms, meeting consumers' daily purchase and stockpiling needs.

Small bag filling machine for instant coffee powderFeatures

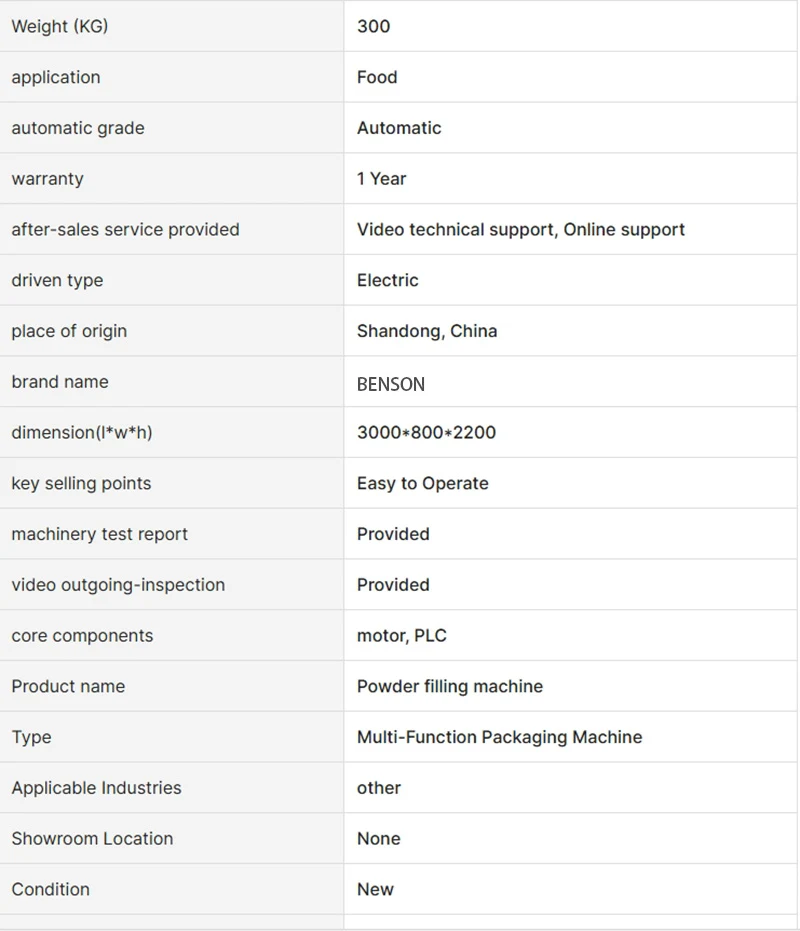

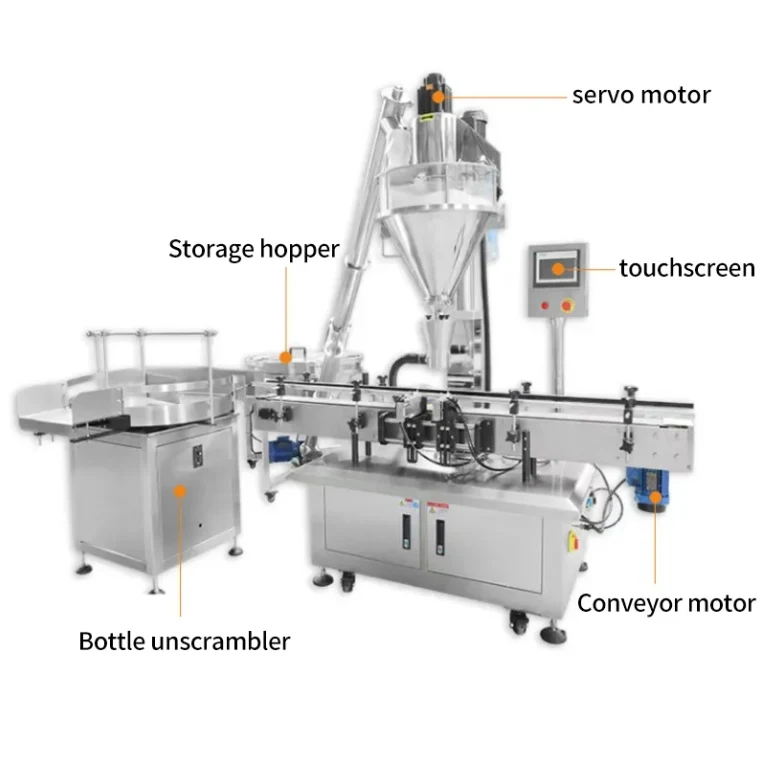

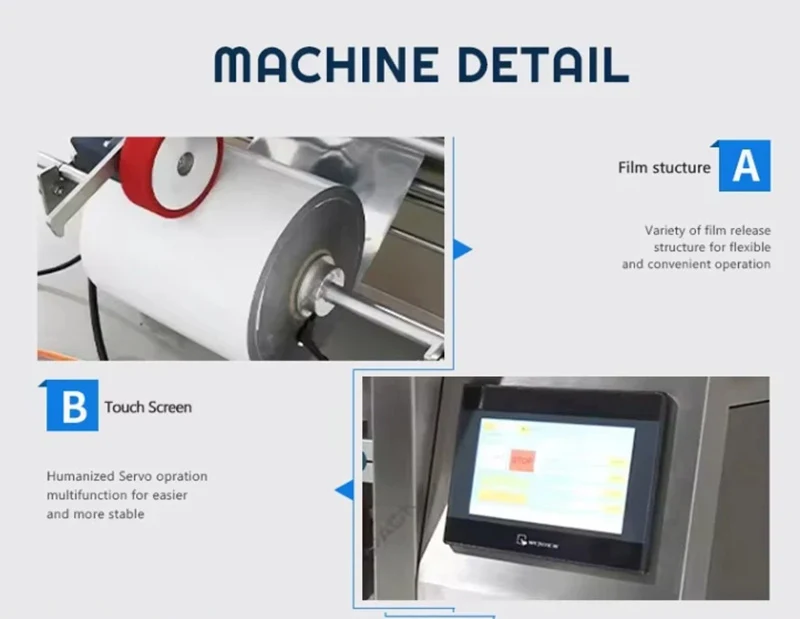

1. Intelligent control: Equipped with an advanced PLC control system and a touch screen operation interface, it is simple and intuitive to operate. Parameters such as filling weight, sealing temperature, and packaging quantity can be quickly set, and the running status of the equipment can be monitored in real time.

2. Flexible model change: It is designed with modular components. When changing the packaging specifications, only a few components need to be simply adjusted or replaced to quickly switch to the production of small bag packaging of different sizes and styles.

3. Anti-dust design: Aiming at the characteristic that coffee powder is prone to dust generation, a fully enclosed filling system and a dust suction device are adopted, effectively reducing dust overflow, keeping the working environment clean, and avoiding raw material waste.

4. Counting and detection: It has an accurate product counting function, which can automatically count the number of packages. With weight detection and sealing quality detection devices, unqualified products can be promptly removed to ensure the quality of products leaving the factory.

5. Energy conservation and environmental protection: The energy consumption design of the equipment is optimized. While ensuring efficient operation, it reduces power consumption, conforming to the concept of green production.

Product Inquiry