The Titanium Dioxide Multi-Functional Packaging Machine Valve Bag Canning System is an integrated intelligent solution specially designed for titanium dioxide packaging operations. Centered on high-precision canning technology, the system integrates multiple functional modules such as automated material conveying, precise metering, and intelligent control. During operation, titanium dioxide is efficiently and stably transported through a closed conveying pipeline to the valve bag filling station

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

The system accurately controls the filling volume of materials, ensuring the weight error of each bag of titanium dioxide is minimized. Additionally, advanced sealing technology is adopted to effectively prevent titanium dioxide dust from spilling during canning, ensuring a clean working environment and the health and safety of operators.

Titanium Dioxide Multi-Functional Packaging Machine Valve Bag Canning System Core Advantages

1. High-Precision Metering: Equipped with high-precision load cells and an intelligent control system, the weight error of each bag of titanium dioxide is strictly controlled within ±0.2kg, effectively ensuring the consistency and accuracy of product packaging weights, and reducing customer complaints and economic losses caused by weight deviations.

2. High-Efficiency Production Capacity: The filling speed can reach 10–15 bags per minute, increasing production efficiency by 30%–50% compared to traditional packaging equipment. This fully meets the packaging needs of large-scale production enterprises, shortens product delivery cycles, and enhances market competitiveness.

3. Multi-Functional Integration: It flexibly adapts to valve bag packaging of different specifications and materials, and is compatible with various types of titanium dioxide products—from general-purpose to special-purpose grades—enabling efficient packaging, reducing equipment replacement frequency, and lowering enterprise equipment investment costs.

4. Energy Conservation and Environmental Protection: The closed canning design and dust recovery system effectively reduce dust emissions during production and minimize environmental pollution. Meanwhile, the equipment has low energy consumption, saving 15%–20% more energy than similar products, aligning with green production concepts and helping enterprises achieve sustainable development.

Titanium Dioxide Multi-Functional Packaging Machine Valve Bag Canning System Wide Applications

1. Coating Industry: Suitable for packaging titanium dioxide in various coating production enterprises. Whether for architectural coatings, industrial coatings, or automotive coatings manufacturers, this system enables efficient and precise packaging of titanium dioxide, ensuring stable raw material supply for coating production.

2. Plastics Industry: In the plastics production field, where titanium dioxide serves as an important white pigment and additive, this canning system meets the diverse packaging needs of plastic enterprises, ensuring accurate dosing and use of titanium dioxide in plastic production.

3. Paper Industry: Used for packaging titanium dioxide in paper-making enterprises. During paper production, titanium dioxide enhances paper whiteness and opacity; the system’s stable operation ensures continuous and efficient supply of titanium dioxide to paper manufacturers.

4. Ink Industry: For ink production enterprises, this system enables precise packaging of titanium dioxide, providing stable-quality raw materials for ink production and helping improve ink product quality and performance.

Titanium Dioxide Multi-Functional Packaging Machine Valve Bag Canning System Notable Features

1. High Automation: The entire packaging process—from material conveying and metering filling to sealing—can be fully automated, requiring minimal manual intervention. This reduces human impact on packaging quality while lowering labor costs and intensity for enterprises.

2. Easy Operation: Equipped with an intuitive and user-friendly human-machine interface, operators can quickly master equipment operation after simple training. Packaging parameters can be easily set via a touchscreen, with real-time monitoring of equipment status for convenient debugging and fault diagnosis.

3. Convenient Maintenance: Adopting a modular design concept, functional components feature clear structures for easy disassembly and replacement. The equipment also includes a complete fault diagnosis system to quickly locate faults, minimize downtime, and improve operational efficiency and service life.

4. Safety and Reliability: Multiple safety protection devices—such as emergency stop buttons, safety light curtains, and overload protection—effectively safeguard operator safety. Key components are made of high-quality materials and undergo rigorous quality testing and performance verification to ensure stable and reliable operation and reduce equipment failure rates.

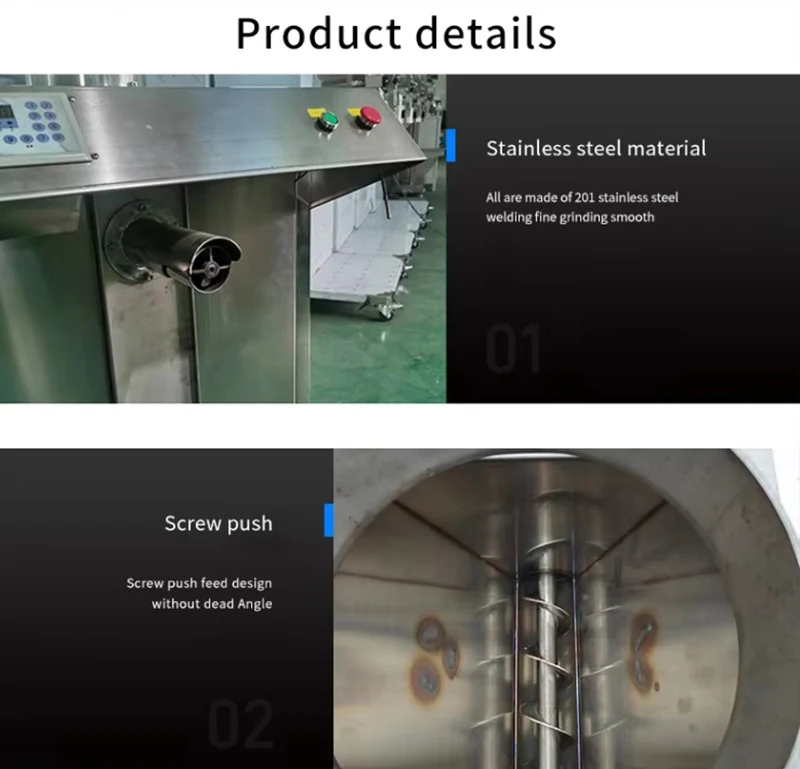

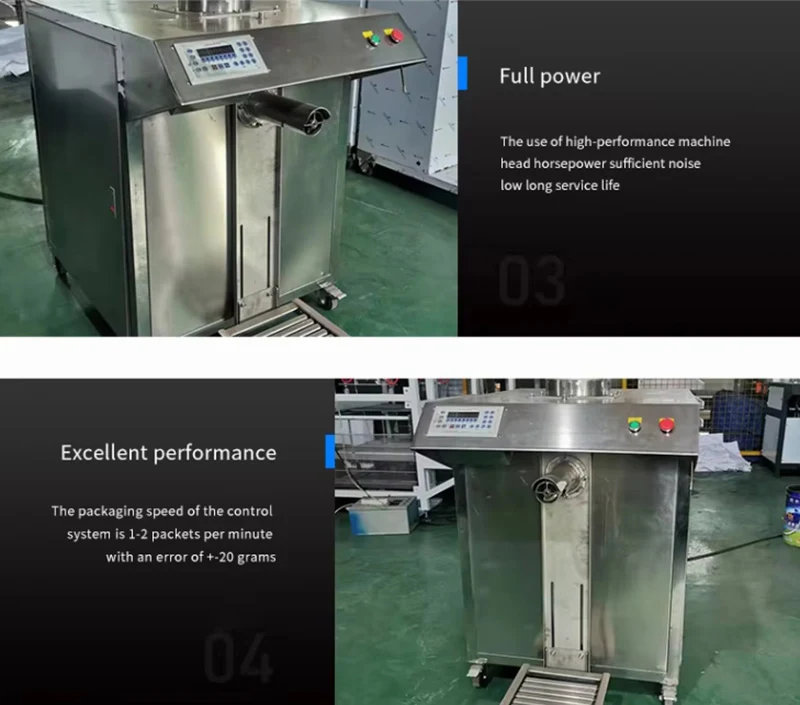

Products Description

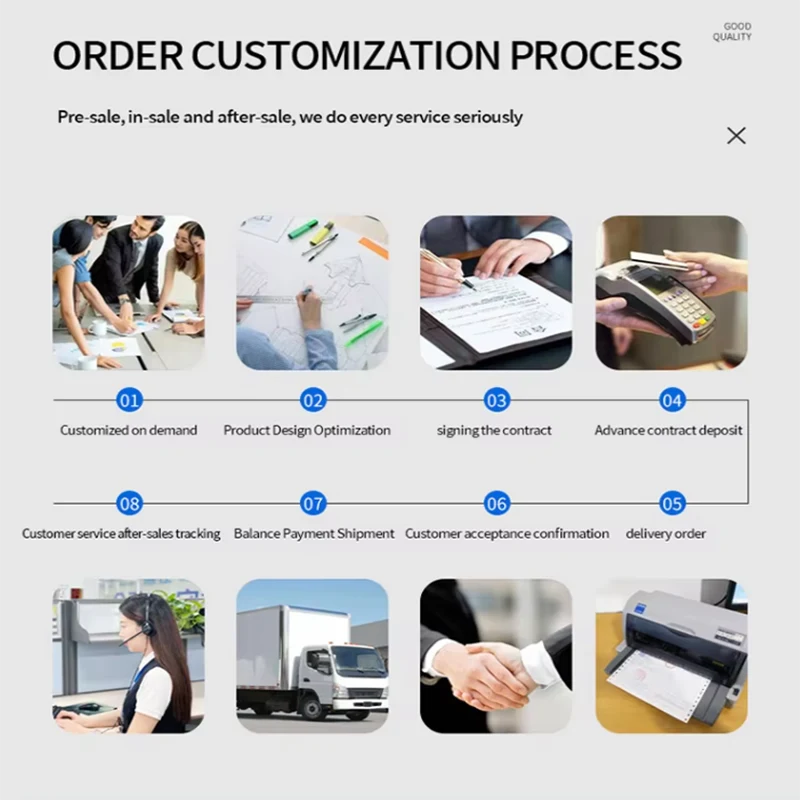

Product Inquiry