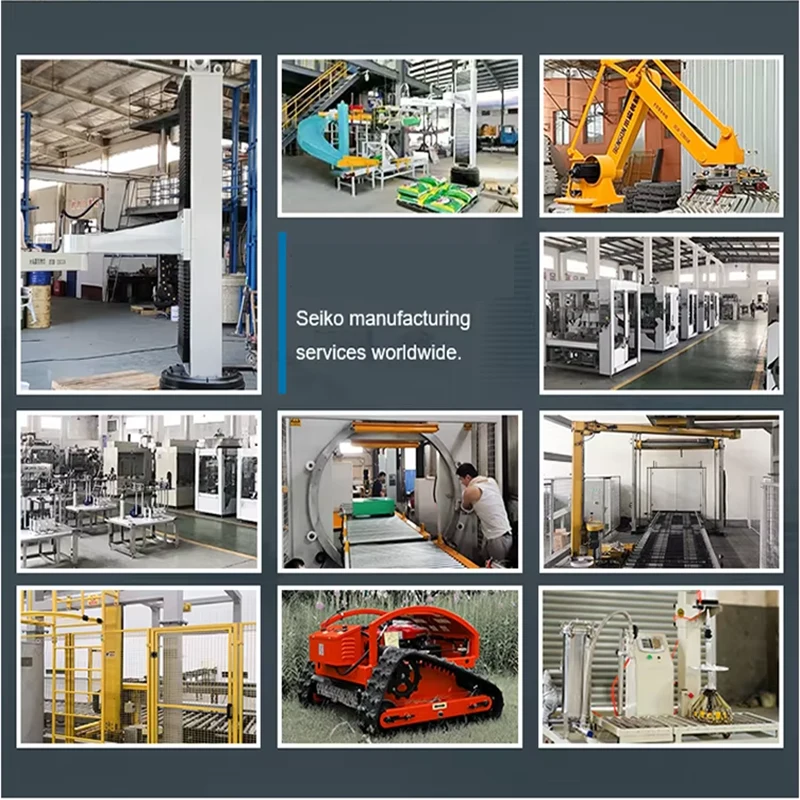

The 25kg Cement Bag Valve Bag Packaging Machine is an automated equipment specially designed for the quantitative packaging of cement, adopting valve bag filling technology. Through a high-precision weighing system and intelligent control system, it can quickly and accurately fill 25kg of cement into valve bags, automatically completing processes such as metering, filling, and sealing, effectively improving packaging efficiency and accuracy.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

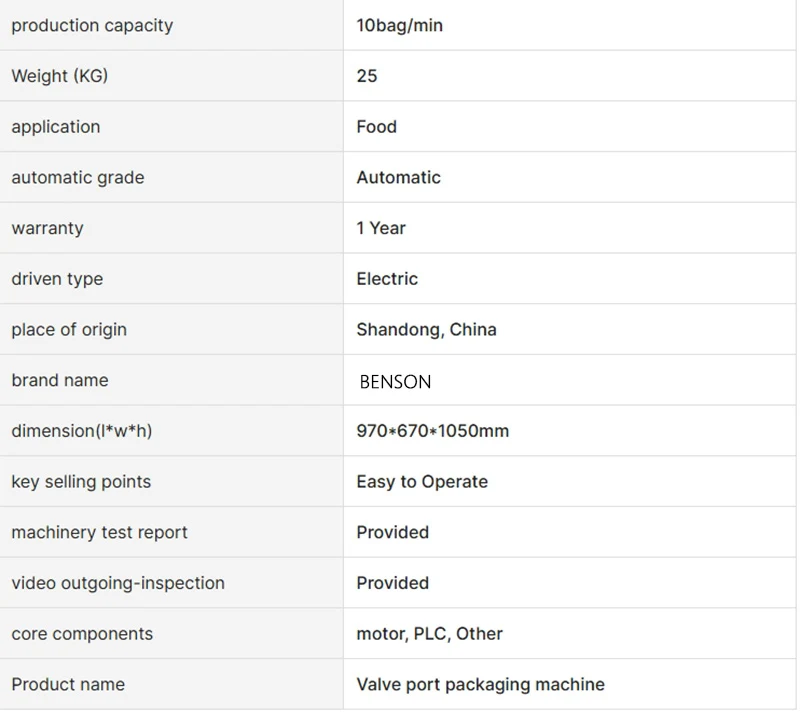

25kg Cement Bag Valve Bag Packaging MachineAdvantages

1. High-efficiency Automation: Achieves fully automated operations from metering to sealing, significantly reducing manual intervention and improving packaging efficiency.

2. High-precision Metering: Equipped with advanced weighing sensors and dynamic compensation technology, packaging errors are controlled within ±0.2% to ensure accurate weight for each bag.

3. Energy-saving and Environment-friendly: Uses a sealed filling structure to reduce dust overflow, minimize environmental pollution, and save material loss.

4. Strong Durability: Core components are made of corrosion-resistant and wear-resistant materials (such as stainless steel and high-strength alloys), adapting to cement dust environments and extending equipment service life.

5. Flexible Adaptability: Supports adjustment of various valve bag specifications and packaging speeds to meet different production needs.

25kg Cement Bag Valve Bag Packaging Machine Applications

1. Building Materials Industry: Mainly used for quantitative packaging of powdery materials such as cement, dry mortar, and gypsum powder.

2. Chemical Industry: Suitable for packaging granular/powdery products such as fertilizers, pigments, and chemical powders.

3. Food Industry: Can package food-grade powdery materials like flour and starch (requires food-grade contact materials).

4. Mining and Metallurgy: Used for packaging industrial raw materials such as mineral powders and metal powders

25kg Cement Bag Valve Bag Packaging MachineFeatures

- Intelligent Control: PLC control system with a touchscreen operation interface supports quick parameter setting and fault self-diagnosis for convenient operation.

- Low Maintenance Design: Modular structure facilitates disassembly and cleaning, and key components (such as valves and conveyor belts) are easy to replace, reducing maintenance costs.

- Safety Protection: Equipped with emergency stop devices and dust explosion-proof systems to ensure operator safety.

- Integrated Design: Can be seamlessly connected with conveying lines, palletizing robots, etc., to build automated packaging production lines.

- Data Management: Supports packaging data statistics and storage for easy production management and quality traceability.

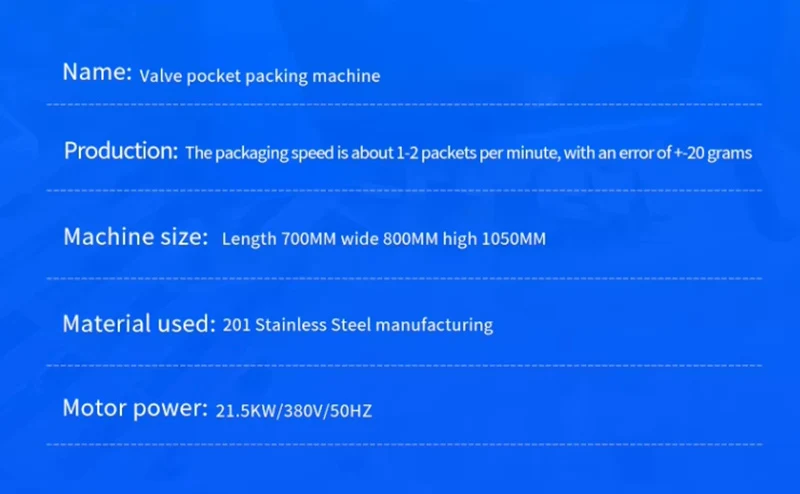

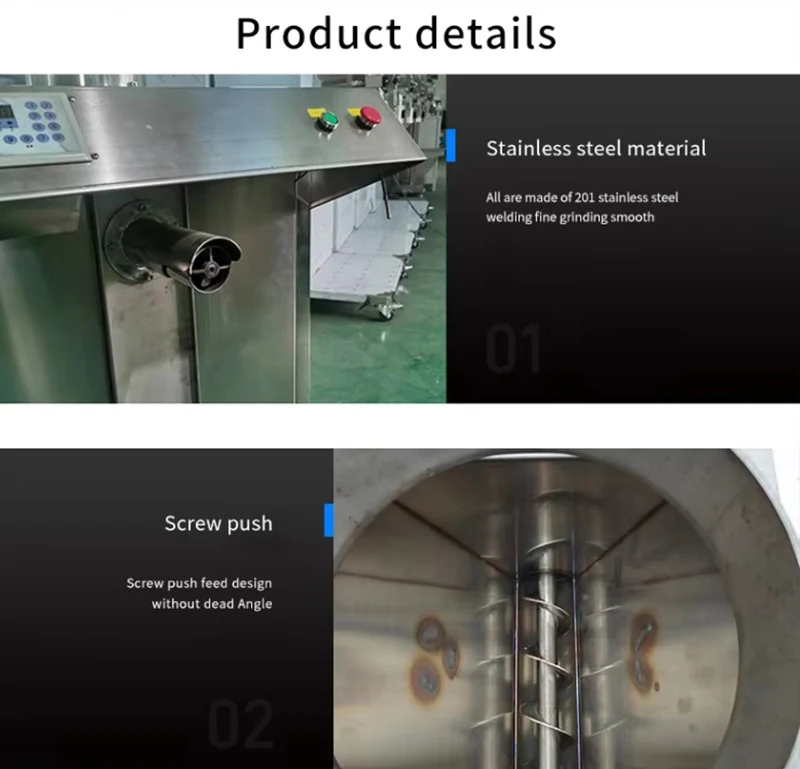

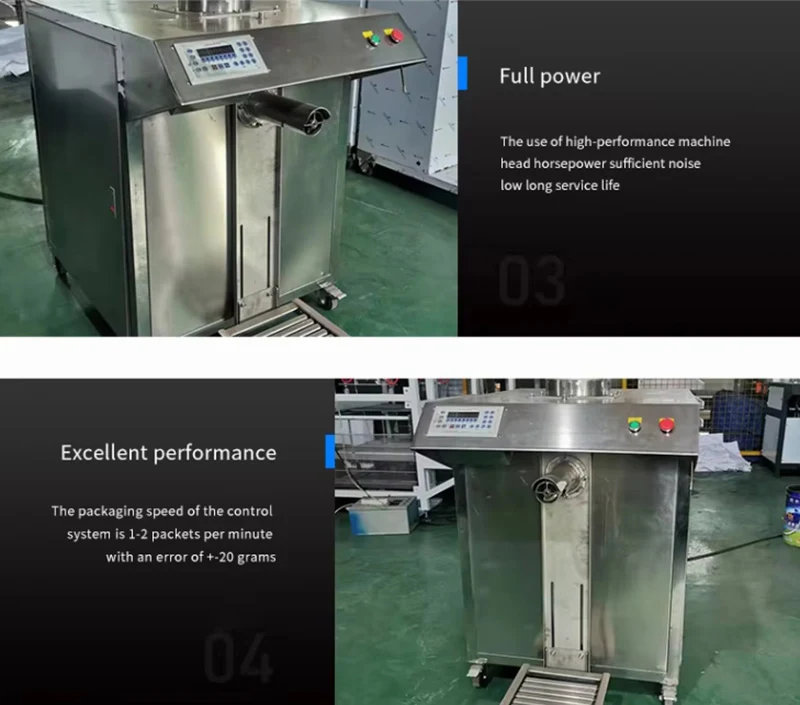

Products Description

<

Product Inquiry