Performance parameters of collaborative robots for automated soybean production

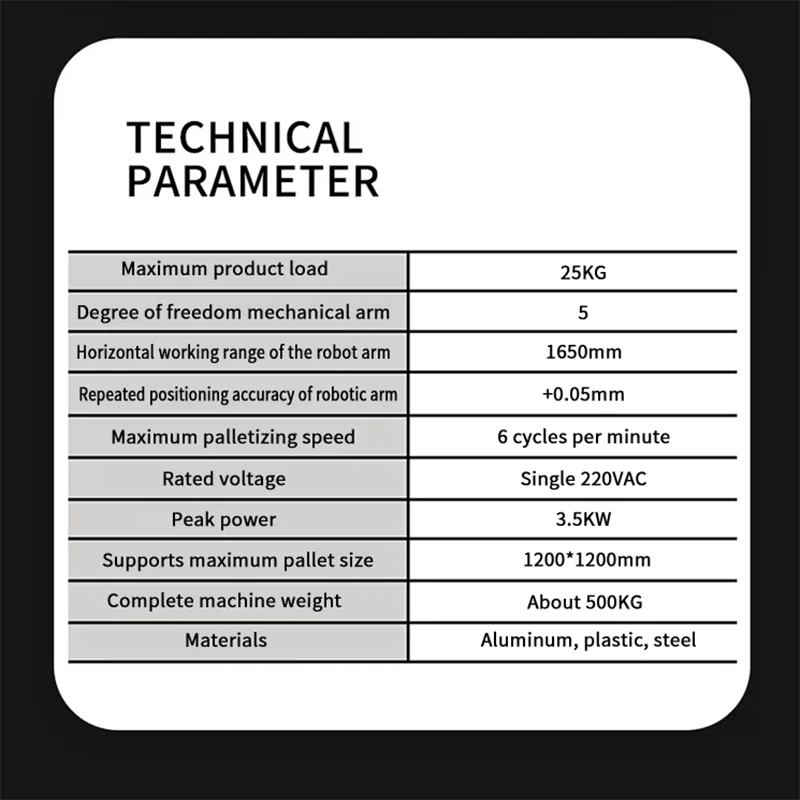

- Load capacity: Rated load is 20kg, and it can stably grasp and carry items within this weight range, such as medium-weight boxes, bags or parts.

- Working radius: Different brands and models vary, generally between 1300mm-1900mm, such as the working radius of the Han's Robot S20 is 1700mm, and the working radius of the Huasheng Control WSC-GD20 Max is 1600mm.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

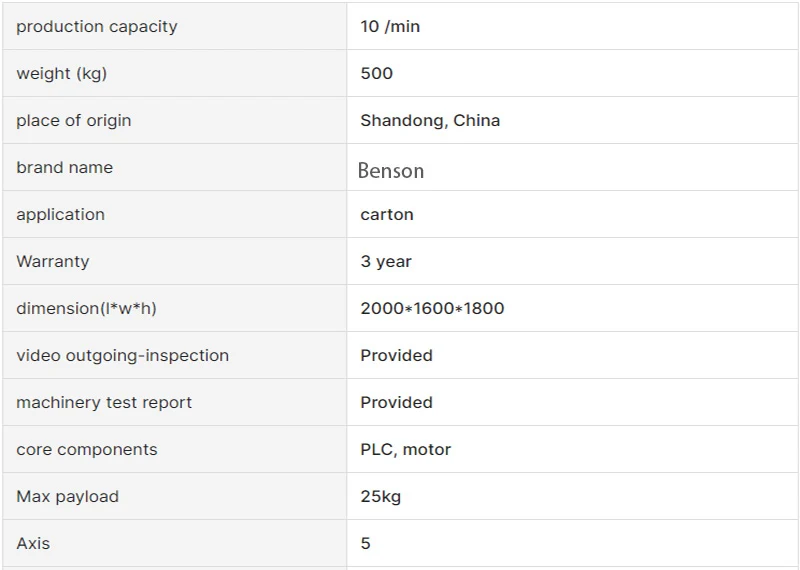

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Key attributes

Industry-specific attributes

Products Description

- Palletizing speed: generally around 8-13 boxes/minute, for example, the palletizing beat of the Han's Robot S20 is 8-12 times/minute, and the beat of the Astro Boy 20KG collaborative palletizing robot is 8-10 boxes/minute.

- Repeat positioning accuracy: some products can reach ±0.05mm-±0.1mm, such as the palletizing accuracy of the Han's Robot S20 is ±0.05mm, and the repeat positioning accuracy of the Ailejia M20 is ±0.1mm.

Product features of collaborative robots for automated production of industrial raw materials

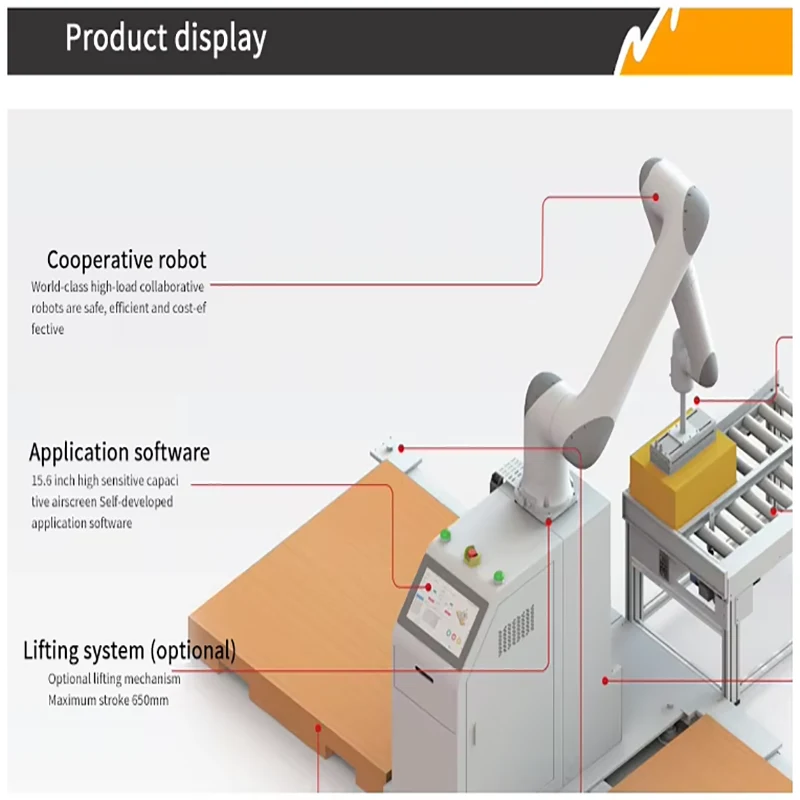

- Easy programming and operation: mostly adopt intelligent and graphical programming modes, such as drag-and-drop programming, without professional programming knowledge, operators can quickly get started, and can easily perform task allocation, workflow and rhythm optimization.

- High safety performance: equipped with a variety of safety sensors and mechanisms such as torque limitation, emergency stop button, collision detection system, etc., when interacting with human operators at close range, it can detect collisions or abnormal situations in time, automatically stop or adjust actions, and ensure personnel safety.

- Flexibility and flexibility: The robot's joints and arm span are flexible and can adapt to different working spaces, palletizing shapes and stacking modes. It can also quickly switch tasks at any time according to production needs to adapt to diverse production needs.

- Good mobility: Some robots are designed to be light and compact and easy to move, such as the Omron TM20, which can be moved throughout the facility with mobile robots and flexibly operate between different production lines and workstations without the need for additional handling equipment.

- Good environmental adaptability: Some robots are optimized for specific industry environments, such as using clean and hygienic solutions to provide suitable palletizing options for industries such as food, medicine, and cosmetics; others have explosion-proof functions and can work in hazardous environments.

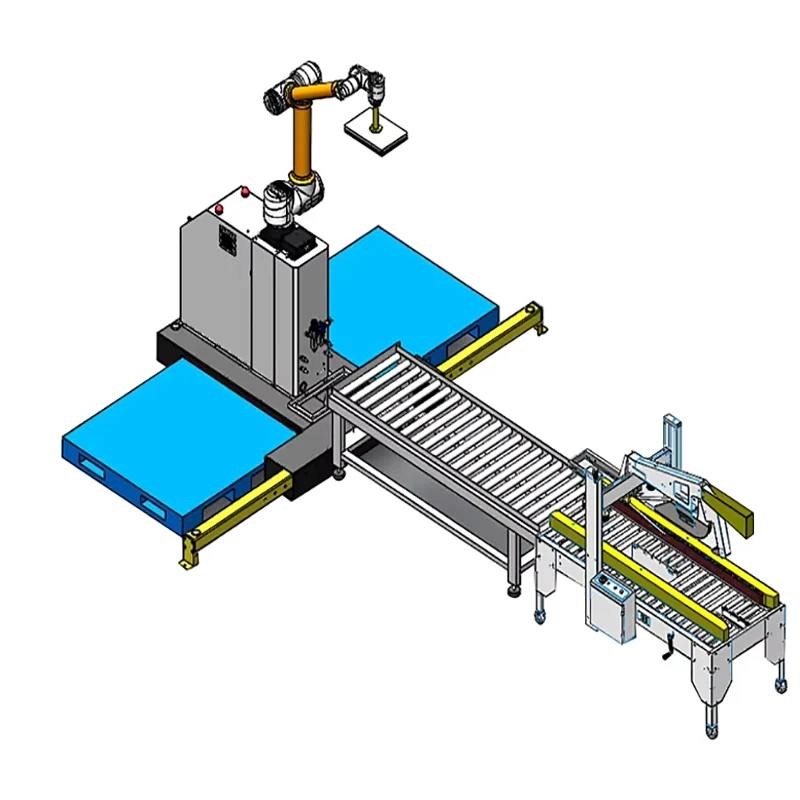

System composition

- Robotic arm: It is the actuator of the robot, usually with multiple joints, which can achieve multi-degree-of-freedom movement to complete actions such as grasping, handling and palletizing.

- End fixture: According to different palletizing items and process requirements, various types of end fixtures such as suction cups and grippers can be selected to grasp and fix items.

- Control system: It is the "brain" of the robot, responsible for receiving and processing various instructions, controlling the motion trajectory, speed, strength and other parameters of the robot arm, and realizing precise palletizing operations.

- Vision system: Some high-end models integrate a vision system, which can automatically identify the location, shape, size and barcode information of items, realize accurate grasping and placement, as well as classification and detection of items.

Company Profile

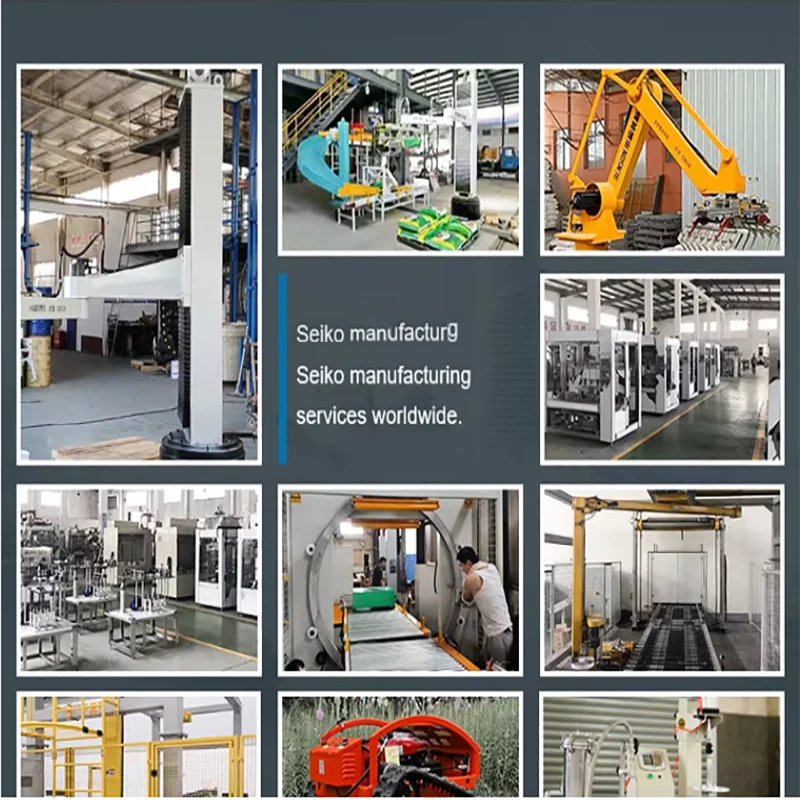

Benson (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and logistics. From product import to output, from electrical control to mechanical structure design, Benson (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

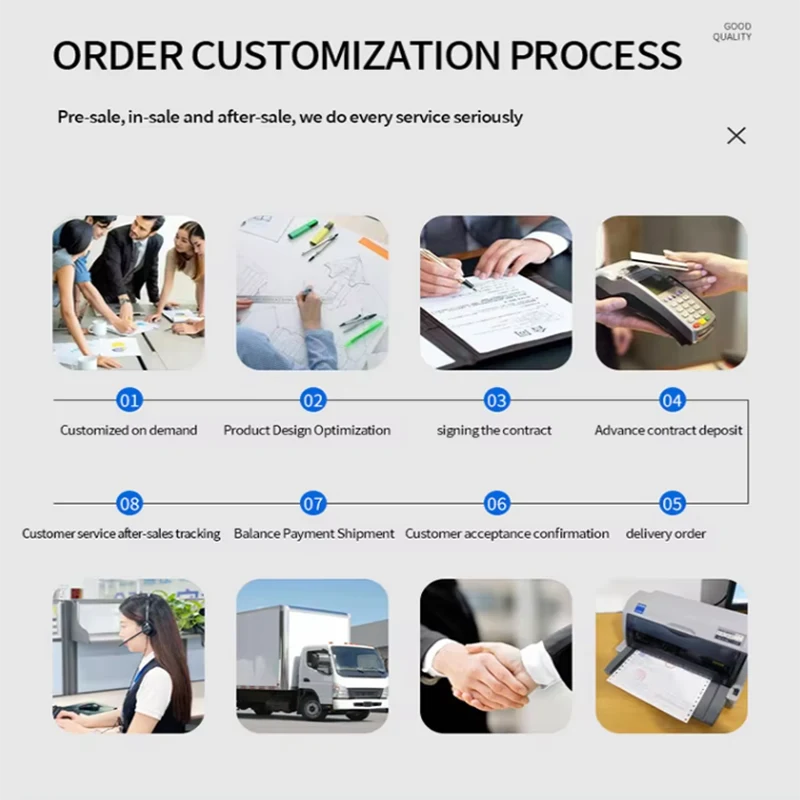

Product Inquiry