180-degree curved conveyor: Expert in efficient material steering and conveying

As an efficient material conveying equipment, the 180 degree curved conveyor can realize the 180 degree turn of materials during the conveying process. It is widely used in production lines of various industries, effectively solving the problems of spatial layout and material flow direction, and improving production efficiency and logistics automation level.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

180 degree curved conveyor structural features

1. Main material: Made of high-quality carbon steel, it has high strength and good wear resistance, ensuring the stability and reliability of the equipment during long-term use.

2. Transmission structure: It adopts sprocket transmission structure, with high transmission efficiency and stable power transmission. It can adapt to the material conveying needs of different loads, and it is relatively convenient for maintenance.

3. Side waist bracket: The roller is lower than the side waist brackets on both sides, forming an effective protective structure, which can prevent the product from running out of the conveying area during the turning process and ensure the safety of conveying.

4. Frame and legs of 180 degree curved conveyor: The frame arc plate and track arc plate are made of 4 mm steel plate laser cutting, with high precision and accurate size; the arc side waist plate is made of 3 mm steel plate bending, and the structure is firm. The legs and brackets are made of 40402 mm carbon steel square tube welding, with strong stability.

5. Foot adjustment: The foot adopts M12 galvanized foot cup, and the height adjustable range is ±30mm. It can be flexibly adjusted according to different ground conditions and usage requirements to ensure the smooth operation of the equipment.

6. Surface treatment: The carbon steel part of the overall frame is sprayed, and the color is aircraft gray. It is not only beautiful and generous, but also has good anti-rust and anti-corrosion properties, extending the service life of the equipment.

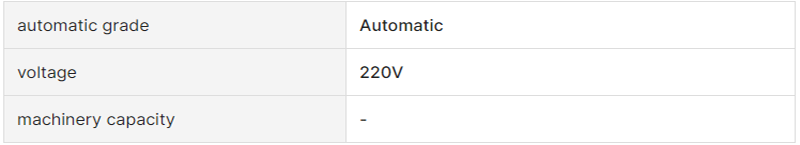

Technical parameters of 180-degree curved conveyor

1. Conveyor speed: 1 - 15 meters/minute, the speed can be adjusted according to actual production needs to adapt to different production rhythms.

2. Drum parameters: It adopts a power conical drum with a cone angle of 3.6 degrees and an effective width of 400 mm, which can effectively support and convey materials.

3. Equipment size: The standard size is an inner radius of 600 mm, a height of 500 mm, and a width of 400 mm. It can also be customized according to the special needs of customers.

4. Load capacity: The load range of a single product is 1 - 30KG, and the whole machine bears 150KG, which can meet the conveying weight requirements of various materials.

5. Total weight: about 120KG, which is convenient for the handling and installation of the equipment.

Scope of application of 180-degree curved conveyor

1. Industry application: It is mainly used for corner conveying of products in narrow spaces, and is widely used in electronics, food, logistics, packaging and other industries. Such as the conveying of parts on electronic product production lines, the packaging and conveying of finished products in the food industry, the conveying of parcels in logistics sorting centers, and the transfer of materials in packaging workshops.

2. Material type: It is suitable for the conveying of carton packaging, turnover boxes, pallets and products with relatively flat bottoms, which can ensure the stability of various materials during the 180-degree turning conveying process.

Non-standard customized service, fitting individual needs

The 180-degree turning roller conveyor is a non-standard product. Before placing an order, you only need to provide detailed parameters, and our professional design team will tailor exclusive equipment for you.

1. Material details parameters: provide the length, width, height, weight data of the conveyed material and the type of material, so that we can design a suitable conveying solution according to the material characteristics.

2. Outer packaging information: inform the type of material outer packaging, such as cans, cartons, wooden boxes, pallets, turnover boxes, etc., in order to adapt to the conveying needs of different packaging.

3. Working environment conditions: explain the temperature (normal temperature or special temperature), humidity (light humidity, dryness or other humidity conditions), pollution (dust, granular waste, oil pollution, etc.) of the working environment. We will select appropriate materials and protective measures to ensure the normal operation of the equipment in a complex environment.

We have a professional design team, which can tailor the most suitable 180-degree curved conveyor for you according to the parameters you provide and the actual use needs, to ensure that the equipment perfectly matches your production process and provide strong support for your business development.

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry