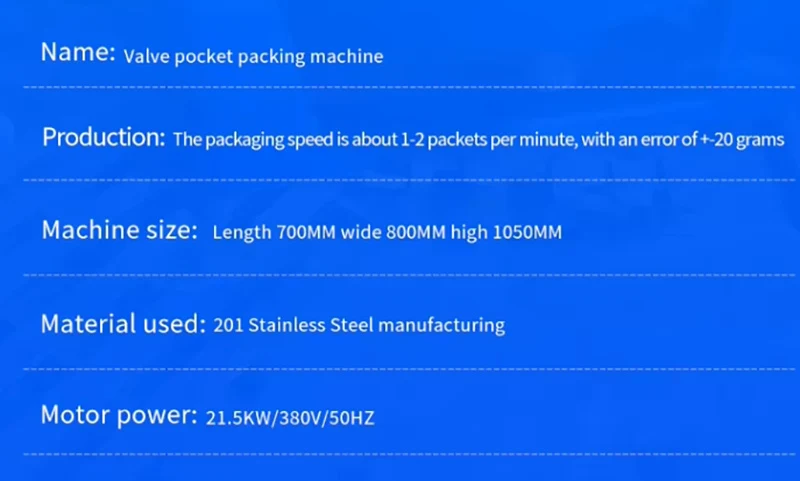

The woven valve pack concrete filling machine is specialized equipment designed for the efficient and accurate filling of concrete into woven valve packs. It integrates advanced mechanical and control systems, featuring an automated feeding mechanism, precise measurement components, and a stable filling structure. The machine can handle various types of concrete, adjusting parameters according to different mixing ratios and work requirements, ensuring that the filling process is smooth

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

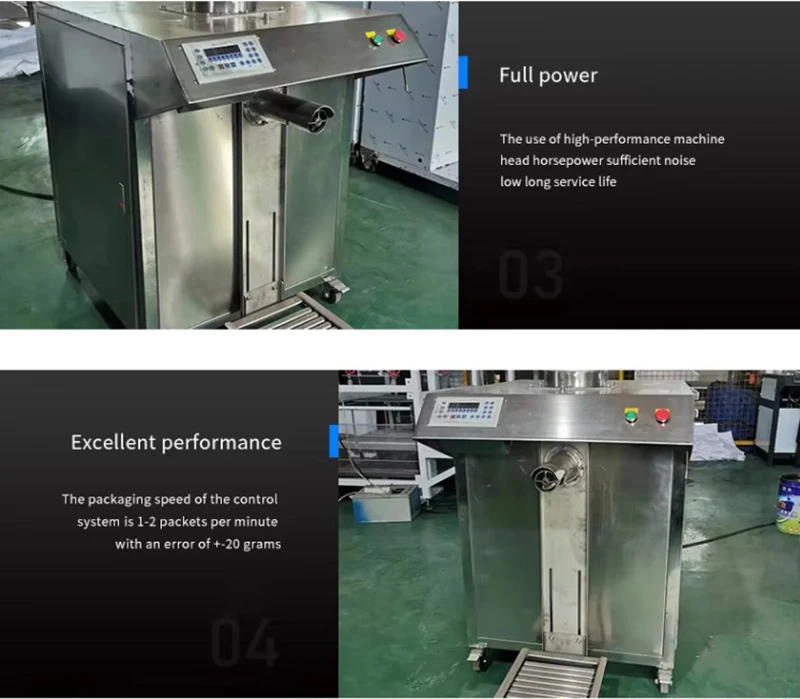

Woven valve pack concrete filling machineAdvantages

1. High Efficiency:With a high - speed filling capacity, it can significantly increase production output compared to traditional manual or semi - automatic filling methods, greatly improving work efficiency and reducing production cycle times.

2. Precise Measurement:Equipped with high - precision weighing and measuring systems, it can accurately control the amount of concrete filled into each valve pack, minimizing material waste and ensuring product consistency.

3. Flexibility:Capable of adapting to different specifications and sizes of woven valve packs, as well as various concrete formulations, meeting the diverse needs of different projects and production scenarios.4. Reduced Labor Intensity:Automated operation reduces the reliance on manual labor, alleviating the heavy workload of workers and reducing the potential for human - error - related quality issues.

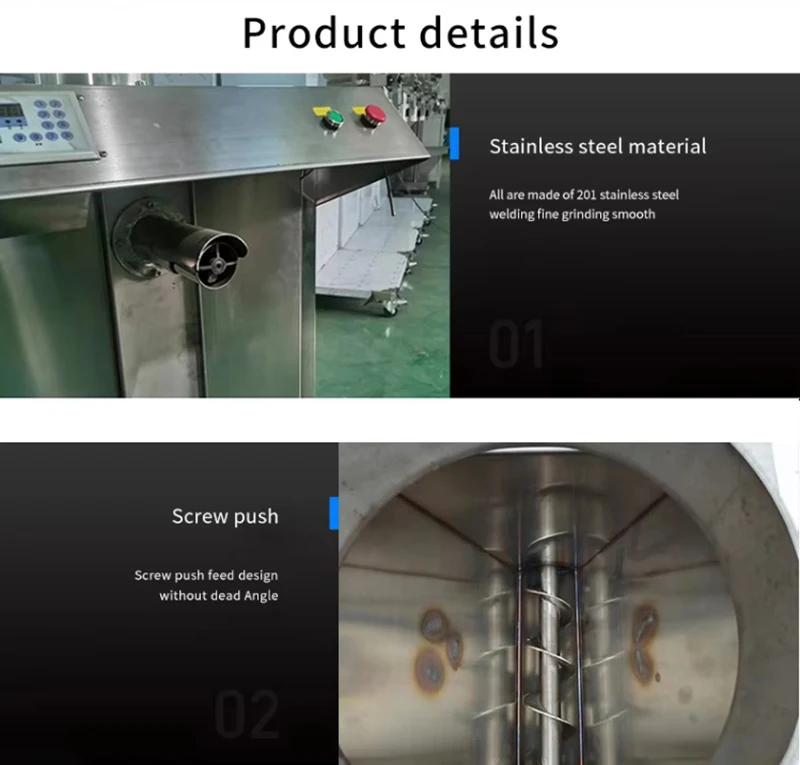

5. Reliable and Durable:Constructed with high - quality materials and components, the machine has a long service life and stable performance, with low failure rates and reduced maintenance costs over time.

Woven valve pack concrete filling machineApplications

1. Construction Industry:Used in the production of precast concrete products, such as concrete blocks, pipes, and slabs. The filled woven valve packs can be easily transported and used on construction sites for rapid installation.

2. Infrastructure Projects:Ideal for large - scale infrastructure projects like road construction, bridge building, and tunnel engineering, where a large quantity of concrete needs to be efficiently filled and transported in a contained manner.

3. Landscaping and Decorative Concrete:Suitable for producing decorative concrete elements used in landscaping, such as garden stones, planters, and decorative tiles, providing an efficient filling solution for small - to medium - scale production runs.

4. Agricultural Facilities:Applied in the construction of agricultural buildings, irrigation channels, and other concrete - based agricultural infrastructure, ensuring the timely and accurate filling of concrete for these projects.

Woven valve pack concrete filling machine Characteristics

1. Automated Operation:The machine features a high - degree of automation, from concrete feeding, measurement, to filling, minimizing the need for manual intervention and ensuring continuous and stable operation.

2. User - friendly Interface:It is equipped with an intuitive control panel, making it easy for operators to set parameters, monitor the filling process, and adjust operations, even for those with limited technical experience.

3. Safety Features:Incorporates multiple safety devices, such as emergency stop buttons, safety guards, and overload protection systems, to ensure the safety of operators and prevent accidents during operation.

4. Easy Maintenance:Designed with a modular structure, components are easy to access for inspection, cleaning, and replacement, reducing downtime for maintenance and facilitating long - term operation.

5. Low Noise and Vibration:Advanced design and manufacturing techniques reduce the noise and vibration generated during operation, creating a more comfortable working environment and reducing the impact on surrounding areas.

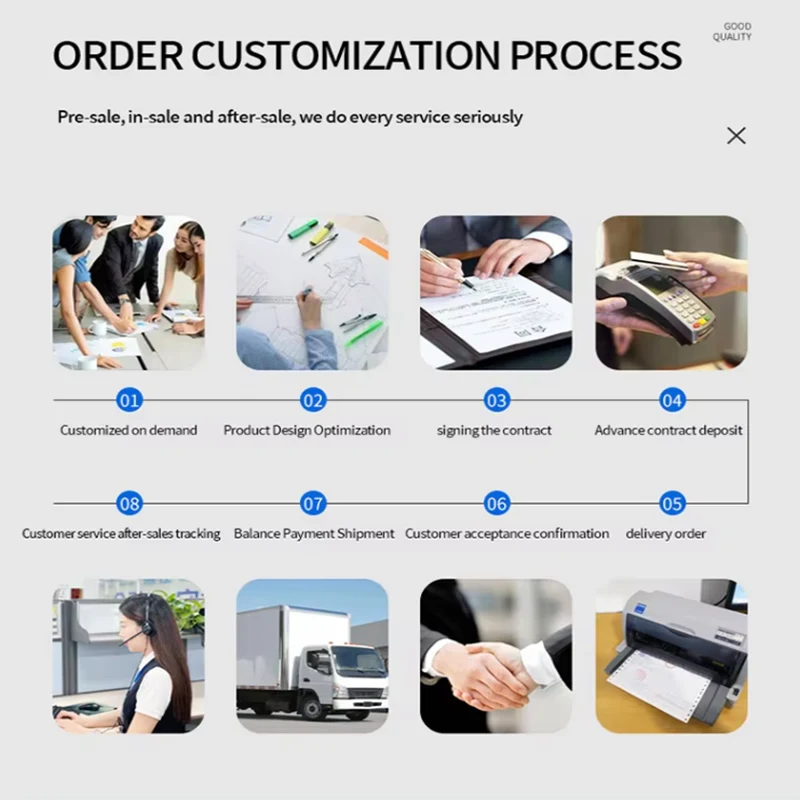

Product Inquiry