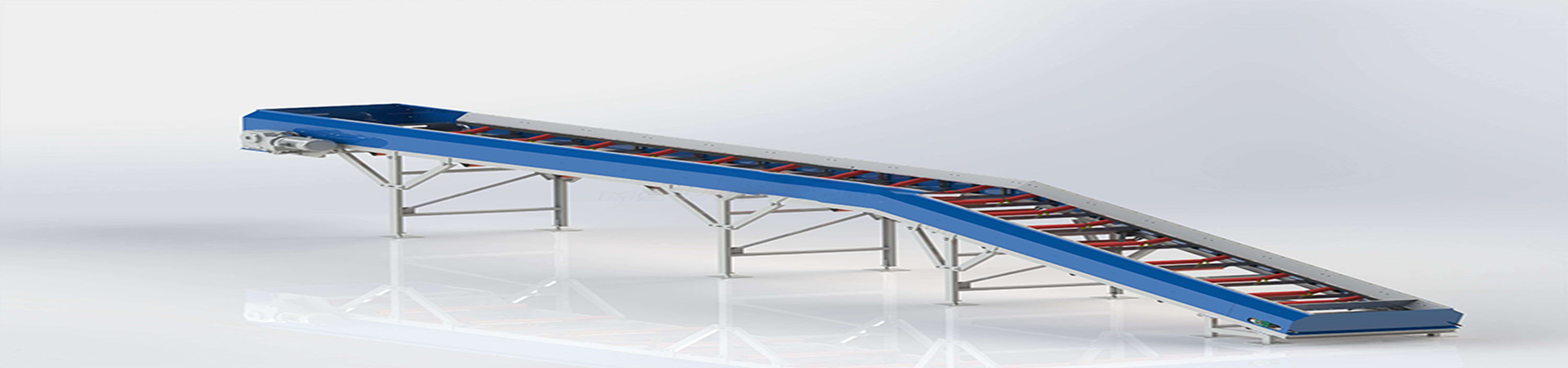

Powered Telescopic Roller Conveyor Energy-saving Operation: This conveyor is powered by 220V electricity, which reduces energy consumption and minimizes environmental impact.

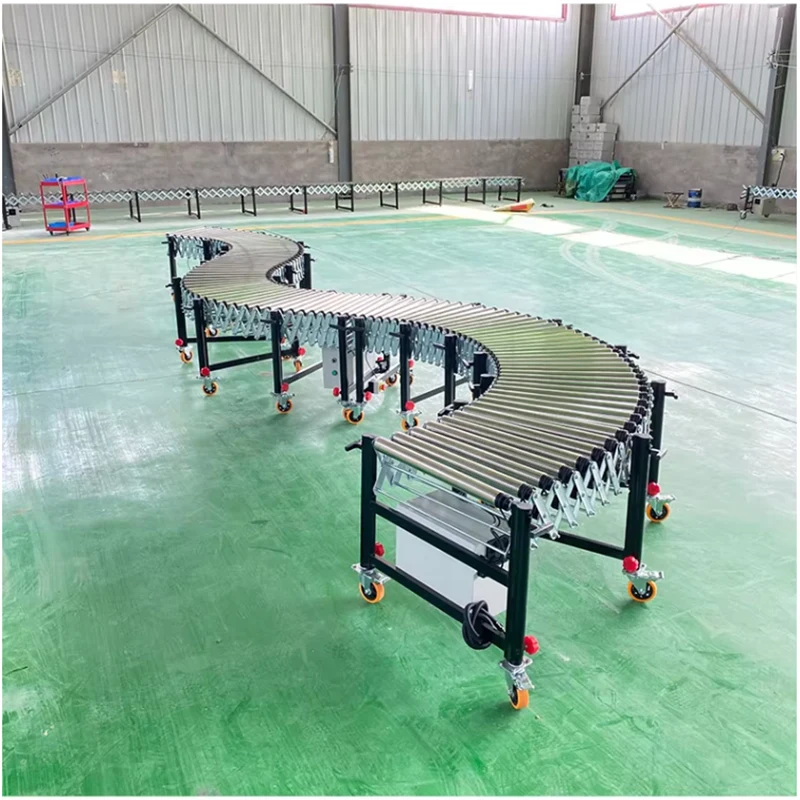

Powered Telescopic Roller Conveyor Flexible Expansion: The telescopic design allows for easy expansion or reconfiguration to accommodate changing production needs, making it an ideal solution for dynamic manufacturing environments.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Powered telescopic roller conveyor is a conveying equipment with power drive and flexible adjustment in length, etc.

Structural features

- Telescopic frame: The frame is constructed with extendable components, which can be freely extended and retracted in the length direction. The longest and shortest ratio of the unit can be up to 3 times. Common specifications include two-section, three-section, four-section, etc. It occupies a small area after contraction, and can meet long-distance transportation when extended. For example, the logistics warehouse can extend the conveyor during peak hours of goods in and out, and contract it during non-peak hours to save space.

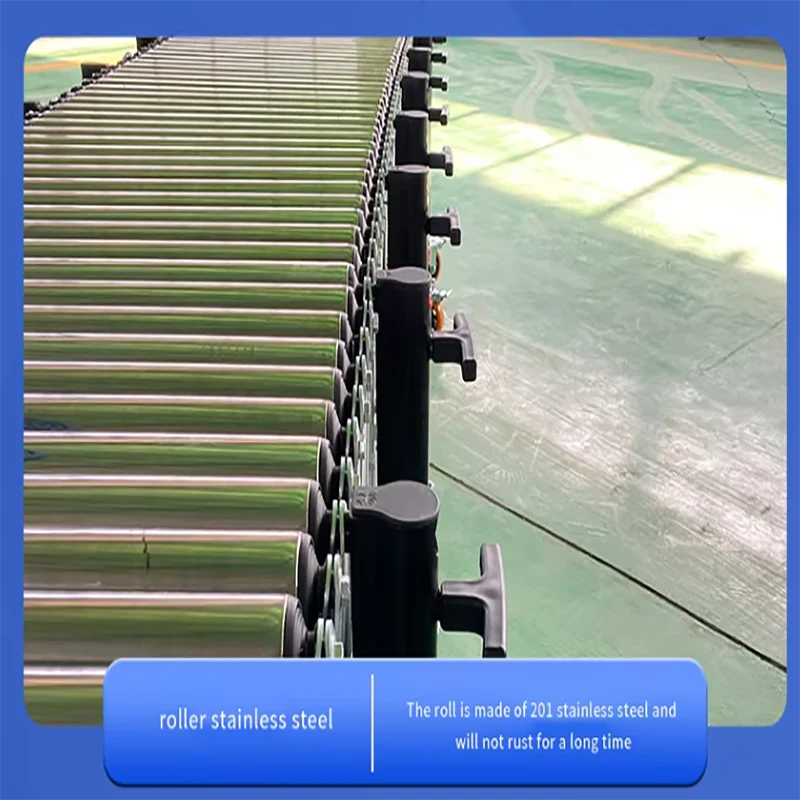

- Diverse conveying carriers: The conveying carrier can be a roller or a wheel. The roller material is diverse, such as carbon steel galvanized, stainless steel, aluminum alloy, rubber coating, PVC, etc.; the roller has nylon Furley wheel, galvanized Furley wheel, etc.

- Flexible steering components: The direction of the body is easy to change, and the conveying direction can be flexibly changed, up to 180 degrees, to meet the needs of different layouts and process routes. Like express sorting centers, cargo diversion can be achieved by changing the conveying direction.

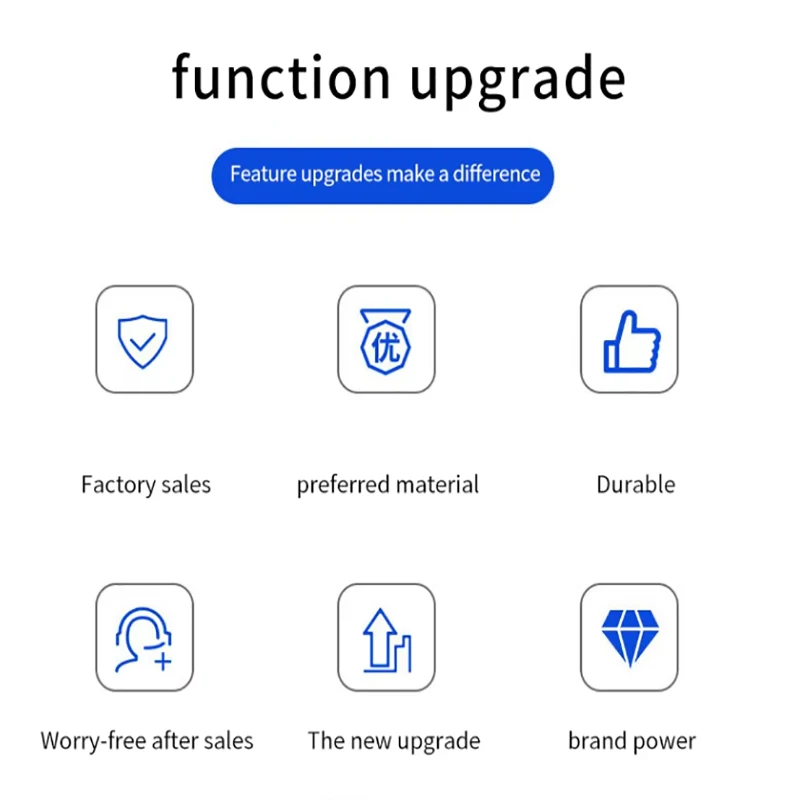

- Adjustable legs and casters: The height of the legs can be adjusted, and casters are installed at the bottom. Some casters have brakes for easy movement and fixing. The position can be moved as needed in the workshop, and the brake is fixed after positioning.

Free replacement parts

Free replacement parts

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

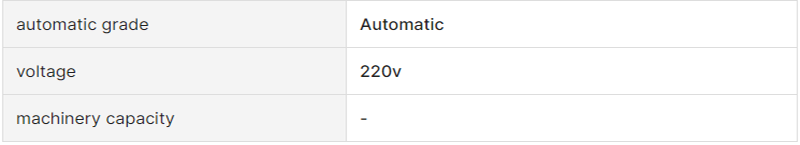

Key attributes

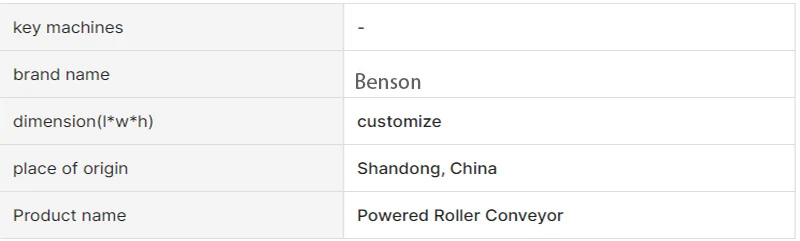

Industry-specific attributes

Other attributes

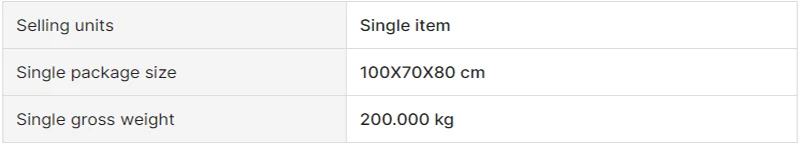

Packaging and delivery

Lead time

Working principle of box-loaded power telescopic roller conveyor

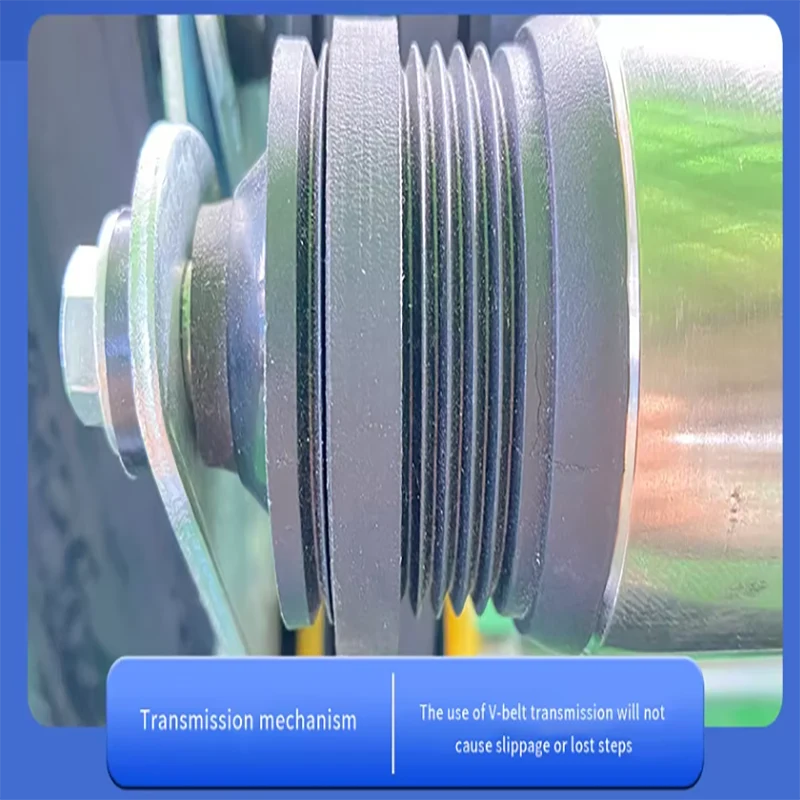

The roller or wheel is driven to rotate by a power device such as an electric roller or a micro motor, and the goods are transported by friction between the roller (wheel) and the goods. Some are driven by chains, PU belts, friction, "O" belts, etc. The motor drives the transmission parts, and then drives the roller (wheel) to do circular motion, so that the goods move along the arrangement direction.

Drive mode

- Electric roller drive: The electric roller has a built-in motor, a compact structure, easy installation, and direct power transmission. It is often used in scenes with high space requirements and short conveying distances.

- Micro motor drive: The power is transmitted to the roller through a transmission device such as a reducer, which can provide a large driving force and is suitable for heavy loads or long-distance transportation.

Technical parameters

- Dimensions: Working length can be customized on demand; working widths are commonly 600mm, 800mm, 1000mm, etc.; working height ranges are 600-800mm, 800-1200mm, 1000-1600mm and some are adjustable.

- Carrying capacity: The unit carrying capacity varies depending on the roller (wheel) diameter and material, such as a 38mm diameter roller carrying 45kg, a 50mm diameter roller carrying 55kg, and a roller carrying 30kg.

- Conveying speed: The conveying speed has fixed speed and variable speed options, and the speed range is generally 0-30m/min, which can be adjusted according to actual production needs.

Application areas

- Logistics industry: In express sorting centers, it is used for cargo sorting and transportation, and the length and direction can be flexibly adjusted to adapt to different operating areas; when loading and unloading goods in warehouses, it is convenient to connect trucks with the internal conveyor lines of the warehouse to improve loading and unloading efficiency.

- Manufacturing industry: production lines such as automobile manufacturing, electronic appliances, etc., used for parts transportation and assembly, which can be flexibly arranged according to the layout of the production line. For example, the automobile parts assembly line accurately transports each component to the assembly station.

- Food and pharmaceutical industries: meet hygiene requirements and are used for product transportation and packaging. For example, biscuits, candies and other products in food factories are packaged and transported to the packing area; pharmaceutical factories transport drugs from production equipment to testing and packaging equipment.

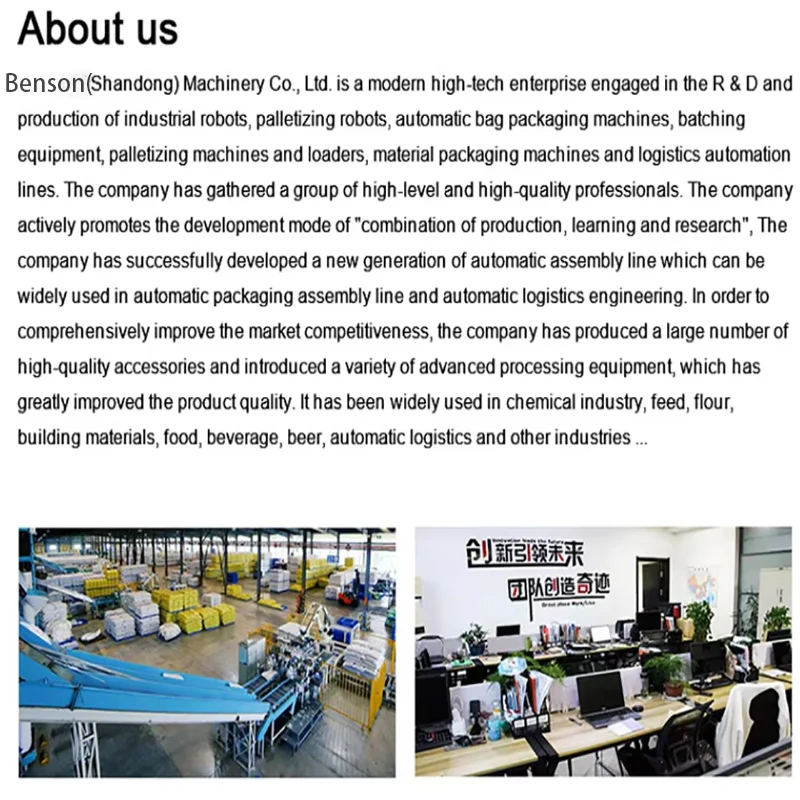

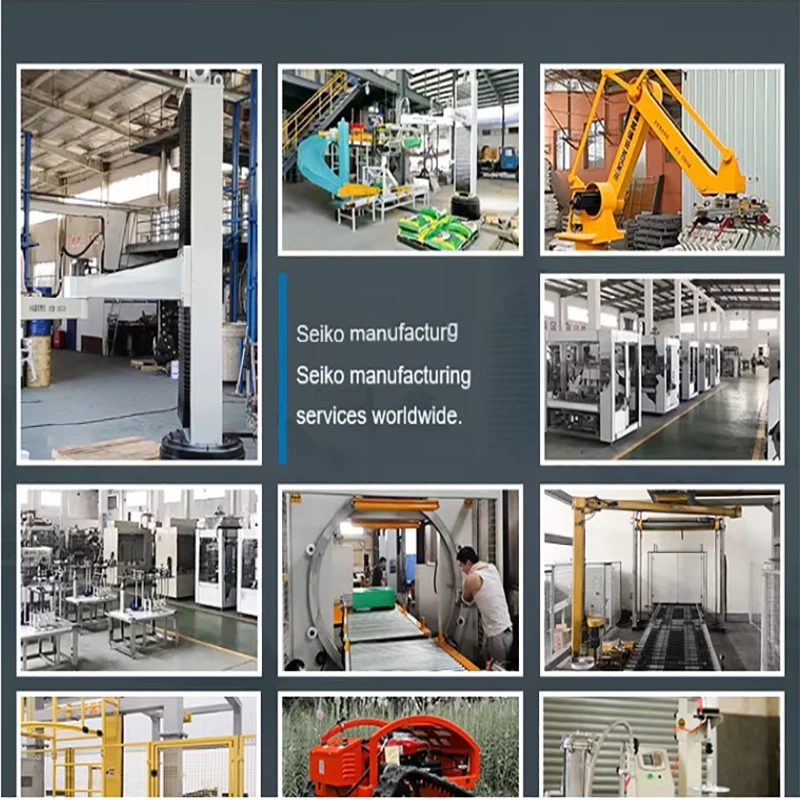

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bomei (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry