Plastic Paper Bag Packaging Machine

The plastic paper bag packaging machine is an advanced piece of industrial equipment designed to automate the packaging process of plastic paper bags. It integrates multiple functions, including bag forming, filling, sealing, and cutting. This machine can handle various types of plastic paper materials, such as laminated paper, coated paper, and composite materials. It is equipped with intelligent control systems, enabling precise operation and adjustment

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Advantages

Plastic Paper Bag Packaging Machine

1. High Efficiency: It can complete a large number of packaging operations in a short time, significantly increasing production capacity compared to manual packaging. For example, it can package hundreds of bags per hour, depending on the model and specification.

2. Consistent Quality: The machine ensures uniform packaging quality. It can achieve consistent sealing strength, bag size, and appearance, reducing the occurrence of defective products.

3. Versatility: It can handle different sizes, shapes, and materials of plastic paper bags, meeting the diverse packaging needs of various industries. Whether it's small - sized product packaging or large - capacity bulk item packaging, this machine can adapt.

4. Cost - Saving: By reducing labor costs and minimizing material waste due to precise operation, it helps enterprises save production costs in the long run.

Dry Powder Sand Filling Machine

1. High - precision Filling: The metering device can achieve high - precision filling, with an accuracy rate often reaching within a very small error range, such as ± 0.5% - 1% of the target filling amount.

2. Adaptability: It can be adjusted to fill different types of dry powder sand with various particle sizes and flow characteristics. Additionally, it can work with different packaging containers, including bags of different sizes and shapes.

3. Dust - control Design: Many dry powder sand filling machines are equipped with dust - control systems. These systems prevent the diffusion of dust during the filling process, creating a cleaner and safer working environment and also reducing material loss caused by dust.

4. Automation and Ease of Operation: With an automated control system, operators can easily set parameters such as filling volume, filling speed, etc. It reduces the need for extensive operator training and simplifies the production process.

. Applications

Plastic Paper Bag Packaging Machine

1. Food Industry: Used for packaging snacks, grains, sugar, coffee, and other food products. The plastic paper material provides good protection against moisture, oxygen, and contaminants, helping to extend the shelf life of food.

2. Pharmaceutical Industry: For packaging medicines, medical powders, and health products. The hygienic and sealed packaging meets the strict requirements of the pharmaceutical industry for product safety and quality.

3. Cosmetics Industry: Ideal for packaging cosmetic powders, lotions in sachets, and other beauty products, providing an attractive and protective packaging solution.

4. Agricultural Products: Can be used to package seeds, fertilizers, and other agricultural items, ensuring the integrity and usability of the products during storage and transportation.

Dry Powder Sand Filling Machine

1. Construction Industry: Widely used for filling dry powder sand used in mortar production, plastering materials, and concrete admixtures. It ensures accurate dosing of sand, which is crucial for the quality of construction materials.

2. Manufacturing of Abrasive Materials: Used to fill abrasive sand into containers, which is essential for industries such as sandblasting, grinding, and polishing.

3. Foundry Industry: For filling sand used in the casting process. The accurate filling of sand helps to form high - quality molds, ensuring the precision of castings.

4. Landscaping and Horticulture: In the production of soil - like mixtures or sand - based growing media, the dry powder sand filling machine can accurately measure and fill the required amount of sand, improving the consistency of the product.

. Features

Plastic Paper Bag Packaging Machine

1. Advanced Control System: Adopts PLC (Programmable Logic Controller) or touch - screen control, which is user - friendly and allows for easy parameter setting and operation monitoring.

2. Self - diagnosis Function: The machine has a self - diagnosis system that can quickly detect faults and display error messages, facilitating timely maintenance and reducing downtime.

3. Adjustable Components: Key components such as the filling nozzle, sealing temperature, and cutting knife position can be adjusted flexibly to adapt to different packaging requirements.

4. Safety Protection Devices: Equipped with safety guards, emergency stop buttons, and other safety features to protect operators from potential hazards during operation.

Dry Powder Sand Filling Machine

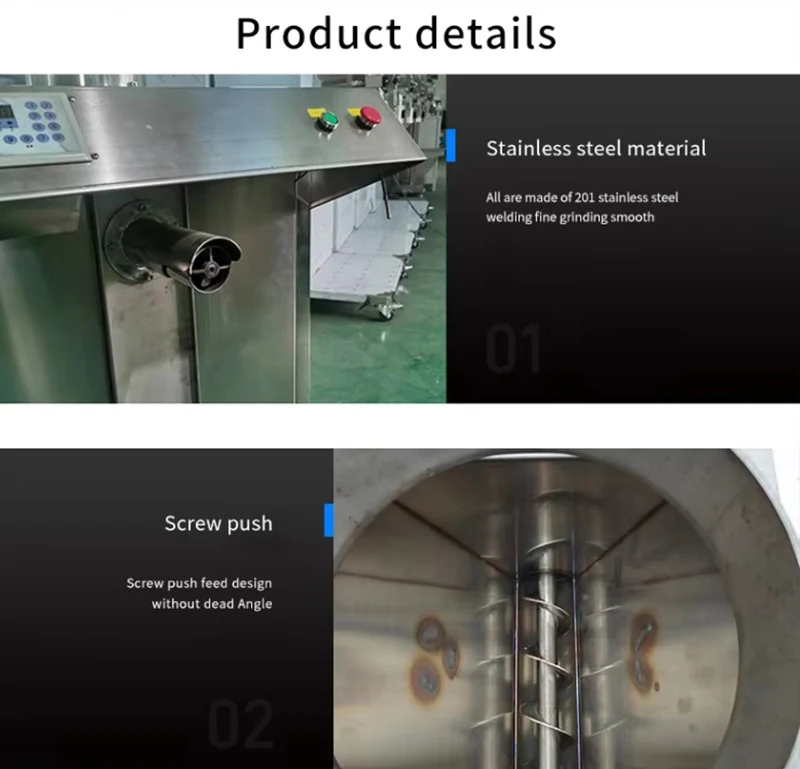

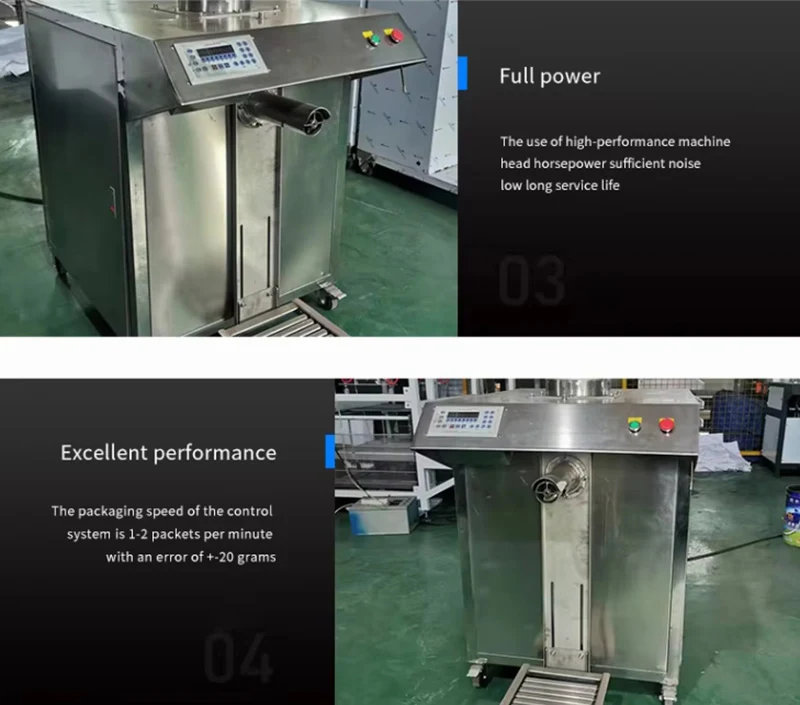

1. Unique Feeding Structure: The feeding system often has a special design, such as screw feeding or vibration feeding, which can ensure a stable and continuous supply of dry powder sand, especially for materials with poor fluidity.

2. High - quality Metering Components: Uses high - precision weighing sensors or volumetric metering devices to ensure accurate measurement of the filling amount.

3. Quick - change Parts: Some components, such as the filling head and metering hopper, can be quickly disassembled and replaced, which is convenient for cleaning and maintenance and also enables the machine to switch between different filling tasks efficiently.

Products Description

Product Inquiry