The electric intelligent automatic cylindrical coding machine is an industrial marking tool integrating advanced technology. With the electric drive system as the core power, it is equipped with an intelligent control system to achieve fully automated operation. It accurately positions through high-precision sensors, and cooperates with special nozzles and ink cartridges. In scenarios such as production lines and logistics warehouses, with extremely fast coding speed and ultra-high resolution,

自动搬运纸箱码垛机单臂码垛机1.结构简单,操作简单灵活,结构耐用,故障率低2.占...

2025-04-28

As a manufacturer of fully automatic org...

2025-06-29

The 15 - kilogram canned goods vertical ...

2025-06-29

The 50-kg intelligent control carton col...

2025-06-28

The 15 - kilogram rice vertical palletiz...

2025-06-27

2025-06-27

The vertical feed stacker is a key equip...

2025-06-15

Thegantry - type high - level palletizer...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

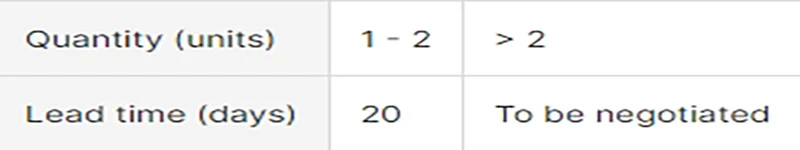

Lead time

Products Description

Electric intelligent automatic column coding machine

The electric intelligent automatic column coding machine is an automated device that integrates advanced technology and innovati

ve design. It is mainly used for efficient and accurate coding and marking of various columnar objects. It adopts an electric drive sys

tem and has an intelligent control program, enabling a series of operations such as automatic feeding, positioning, coding, and disc

harging. This greatly improves production efficiency and reduces labor costs.

The column coding machine is equipped with a high-precision print head. It can clearly print various characters, numbers, barcodes,

QR codes and other information on the surface of the column according to user requirements. The printing quality is clear and fir

m, meeting the marking needs of different industries. Its intelligent control system has good compatibility and expandability, and c

an be seamlessly connected with other production equipment to achieve the automated integration of the production line. At the sa

me time, it also has the functions of automatic fault detection and alarm, which helps operators to quickly detect and solve problem

s, ensuring the stable operation of the equipment. In addition, the operation interface of the electric intelligent automatic column c

oding machine is simple and intuitive, easy to use. Even those without a professional technical background can quickly master the o

peration method.electric intelligent automatic column coding machine Whether it is used for the packaging of cylindrical containers

in industries such as food, medicine, and cosmetics,

or for the marking of columnar parts in fields such as electronics and machinery, the electric intelligent automatic column coding m

achine, with its high efficiency, accuracy, and stable performance, has become a powerful assistant for enterprises to improve produ

ction efficiency and product quality.

Working process of the electric intelligent automatic column coding machine:

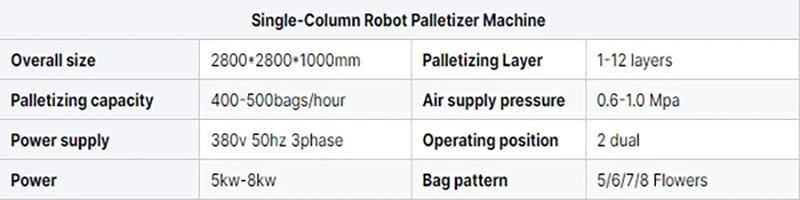

Specification

Main features of the electric intelligent automatic column coding machine:

1.High degree of automation: It can automatically complete a series of operations such as column code printing and pasting without human intervention, greatly improving work efficiency and reducing errors and labor intensity caused by manual operation.

2.Intelligent control: Equipped with an intelligent control system, it can precisely control parameters such as printing content, position, and speed through preset programs. It can also be linked with other production equipment to achieve intelligent management of the entire production process.

3.High - precision printing: Adopting advanced printing technology, it can ensure clear and accurate printing of column codes. The characters are of uniform size and spacing, improving the readability and recognition rate of column codes, which is beneficial for subsequent barcode scanning and data management.

4.Strong adaptability:electric intelligent automatic column coding machine, It can adapt to columns of different specifications and shapes. By adjusting relevant parameters and fixtures, it can print code labels on various types of column bodies, having strong versatility and flexibility.

5.Data management function: It has data storage and management functions, and can record data such as printed column code information, time, and quantity, which is convenient for traceability, statistical analysis, and helps enterprises achieve informatization of quality control and production management.

6.Simple operation: It has a user - friendly interface and a simple and clear operation panel. Staff can operate it proficiently after simple training, reducing the skill requirements for operators.

7.High safety:electric intelligent automatic column coding machine?It is designed with a variety of safety protection devices, such as overload protection and leakage protection, which can effectively prevent equipment failures and accidents, ensuring the safety of operators and equipment.

8.Low maintenance cost: With a reasonable structural design, it uses high - quality components and materials. The equipment runs stably with a low failure rate, and is easy to maintain and repair, reducing maintenance costs and downtime.

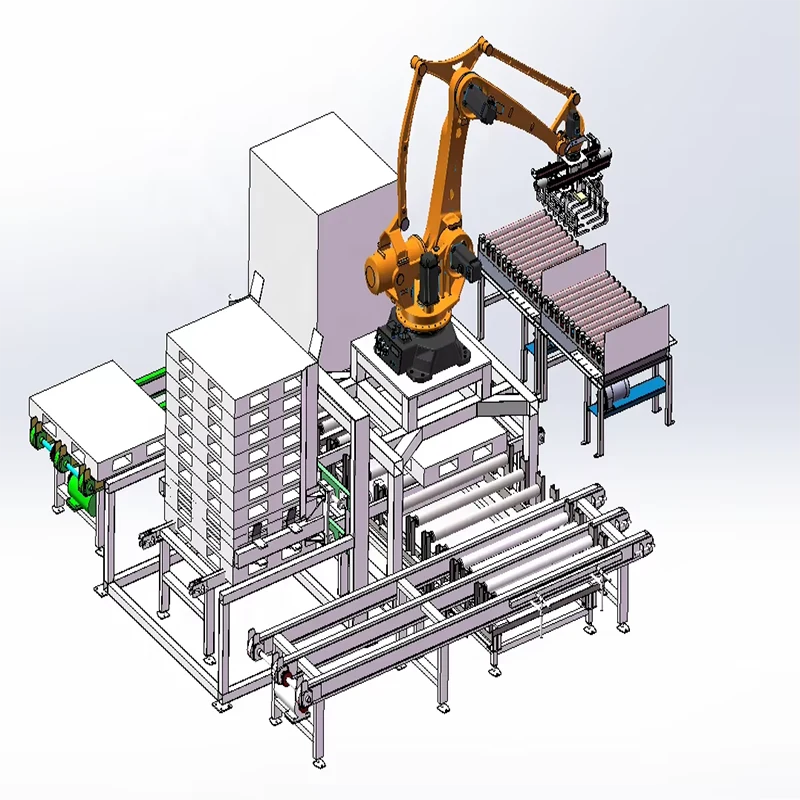

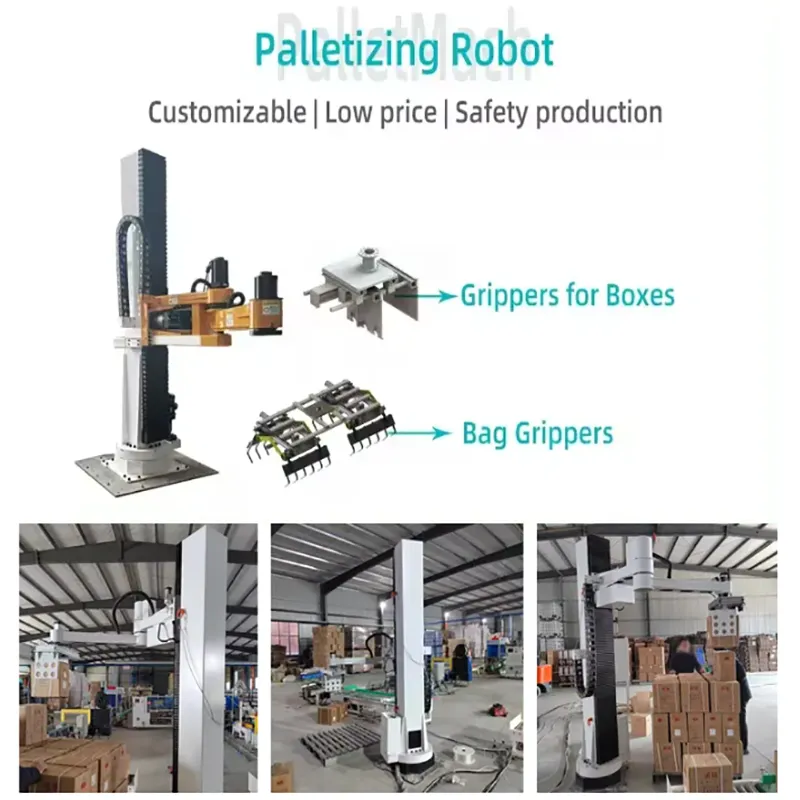

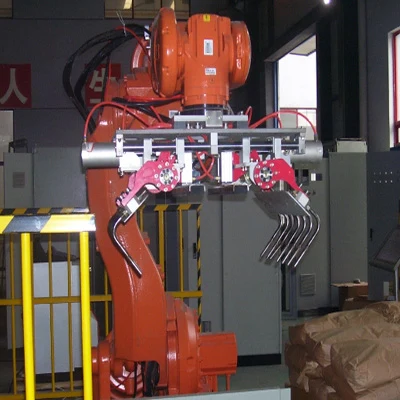

The palletizer features an interchangeable gripper—clamp, suction, or fork—suitable for various materials and shapes.

This ensuressecure, damage-free handling and precise placement, enhancing flexibility and efficiency across different product lines and packaging types.

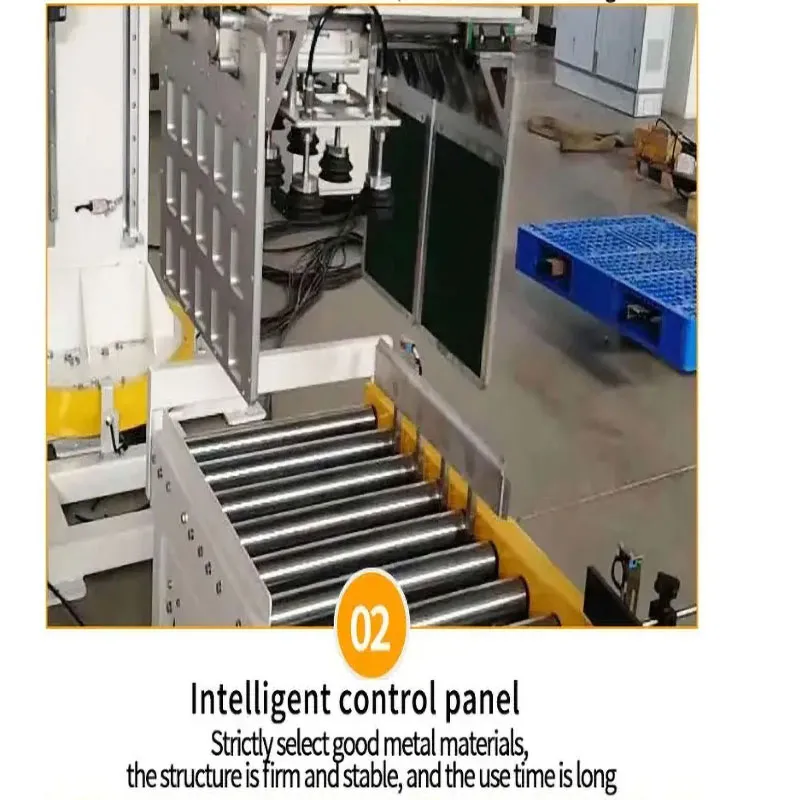

The control cabinet contains all electrical and control components, including PLCs, motor drives, and safety relays. It ensures reliabl

e, safe operation with easy access for maintenance and built-in protection against electrical faults.

Teaching Pendant

The palletizer includes an intuitive teach pendant for easy programming and control. Operators can quickly set pallet patterns,

adjust positions, and monitor status, enabling efficient operation and fast changeovers without technical complexity.

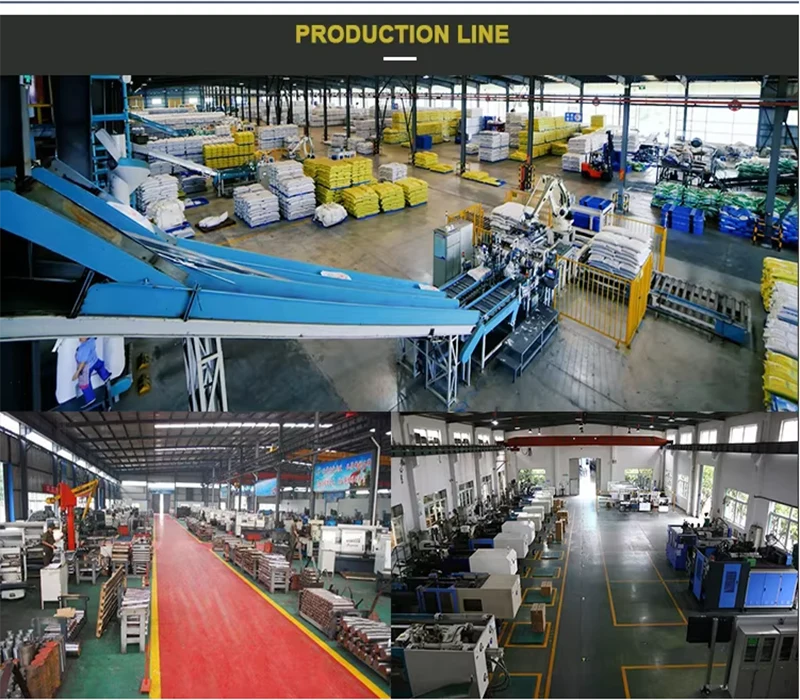

Conveyor System

Handles material transfer and placement with precision; easily integrates into existing packaging systems for streamlined

operations.

https://palletizerobot.com/products/

Advantages of Electric Intelligent Automatic Column Coding Machine:

1.High - efficiency automation: It can automatically complete processes such as column code printing and pasting without the need for manual operation one by one. This greatly improves production efficiency, especially in large - scale production scenarios. It can significantly shorten the production cycle and reduce labor costs.

2.High precision: The intelligent control system precisely controls parameters such as printing content, position, and speed, ensuring the accuracy and consistency of column code printing, reducing errors caused by manual operation, and improving product quality.

3.Strong adaptability: By adjusting parameters and fixtures, it can adapt to columns of different specifications and shapes. Whether they are circular, square, or other special - shaped columns, it can perform code marking and printing. It has a wide range of applications, saving enterprises the cost of equipment replacement.

4.Convenient data management: It has data storage and management functions, capable of recording data such as column code information, printing time, and quantity. This facilitates product traceability, quality control, and production statistical analysis for enterprises, helping to achieve information - based management and improve the enterprise management level.

5.Simple operation:Electric Intelligent Automatic Column Coding MachineIt has a user - friendly human - machine interface, and the operation panel is simple and easy to understand. Staff can start operating after simple training, reducing the professional skill requirements for operators and also reducing the operation risks caused by personnel changes.

6.High safety: It is equipped with a variety of safety protection devices, such as overload protection and leakage protection, which can effectively protect the safety of operators and equipment, reduce the possibility of accidents, and create a safe production environment.

7.Low maintenance cost: It uses high - quality components and a reasonable structural design. The equipment runs stably with a low failure rate. Daily maintenance and repair are relatively convenient, which can reduce equipment downtime, lower maintenance costs, and extend the service life of the equipment.

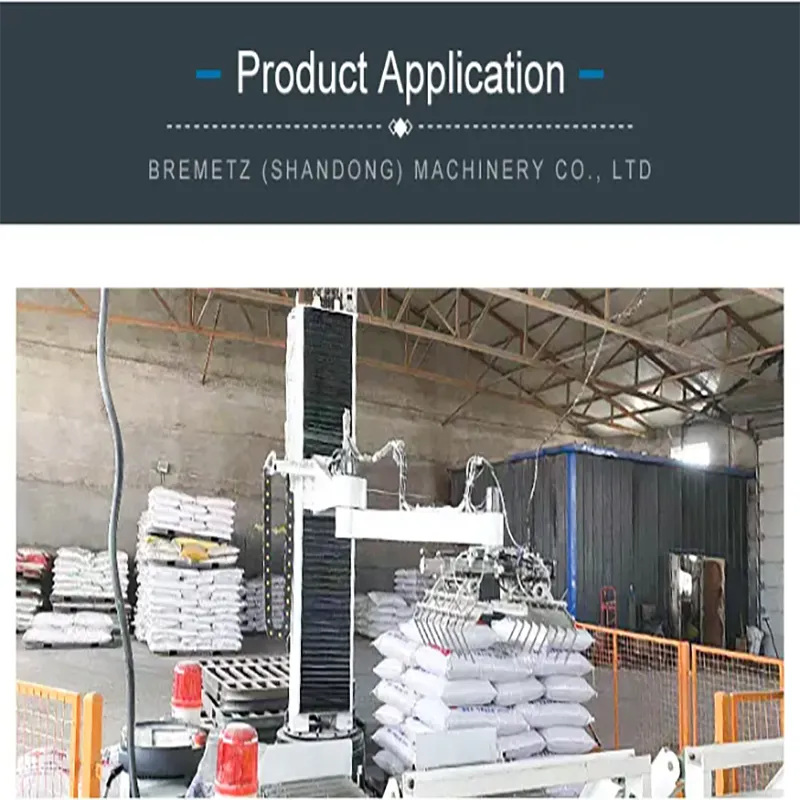

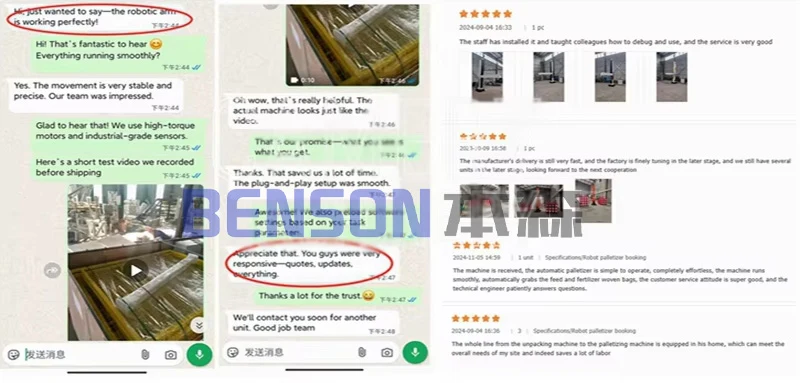

Company Profile

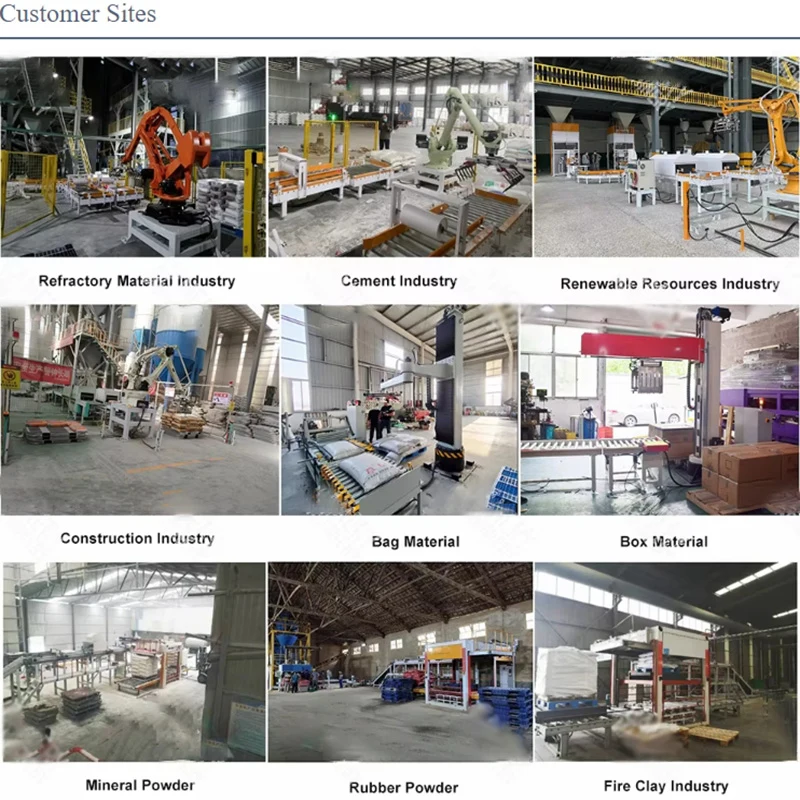

Benson Intelligent Equipment (Shandong) Co., Ltd.was founded in 2013, including self-researching and development,

design, production and sales.

Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizi

ng machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing

and other industries.Benson has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting cou

ntries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided prof

essional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every se

rviced domestic and foreign client. Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-

win, continue to provide our customers with high-end products and quality service.

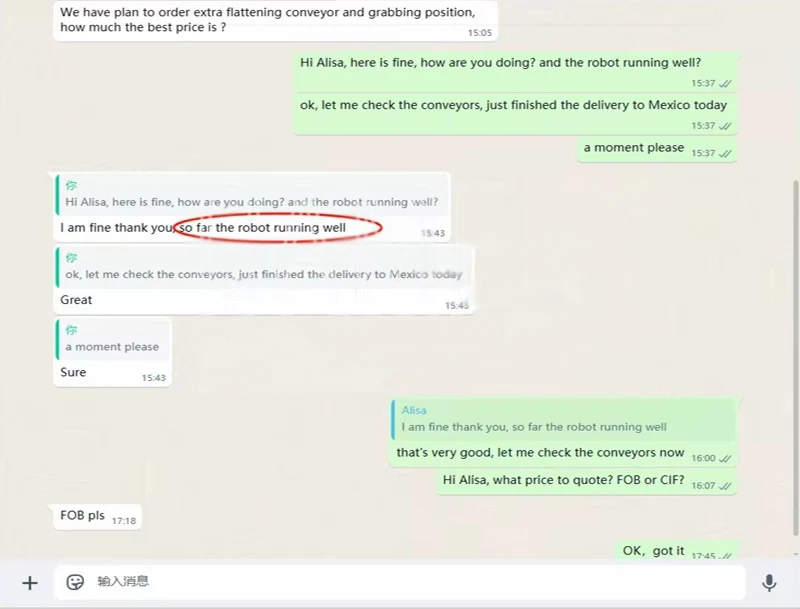

1. Are you factory or trading company?We are the factory, we doing this line for more than 10 years.

2. Can you provide after-sales service for installation?Yes. Before the equipment is shipped, we will install and debug it in the factory to ensure that all components are running stably. After that, the whole set of equipment will be packed in wooden boxes/containers. After receiving the equipment, there is no need for a lot of installation and debugging. At the same time, we will provide corresponding pictures/videos/manuals, and provide telephone consultation online, so that you can ask questions at any time.

If you need to send engineers to the local area to install, debug and train employees, we can also provide you with it. We will provide manuals and detailed videos to help customers install the machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room fees and a daily subsidy of US$150.

3. How long is the warranty on your palletizer robot?

We provide a one-year warranty. If there is any problem with the equipment during the warranty period, we will replace it free of charge. If the warranty period expires, we will provide damaged spare parts at cost price. At the same time, our palletizers use brand components such as Schneider and AirTac, which have more stable performance and longer service life. Please rest assured to buy, we are worthy of your trust.

4. Are there any requirements for pallet size and stacking height?It supports a variety of pallet sizes, and the maximum stacking height can reach 1.8 meters to meet different shipping needs.5. Is there a complete solution with a conveyor line?We can provide a complete line: belt conveyor, automatic bag sorting, steering, bag pressing, palletizing, and integrated delivery.

产品询价