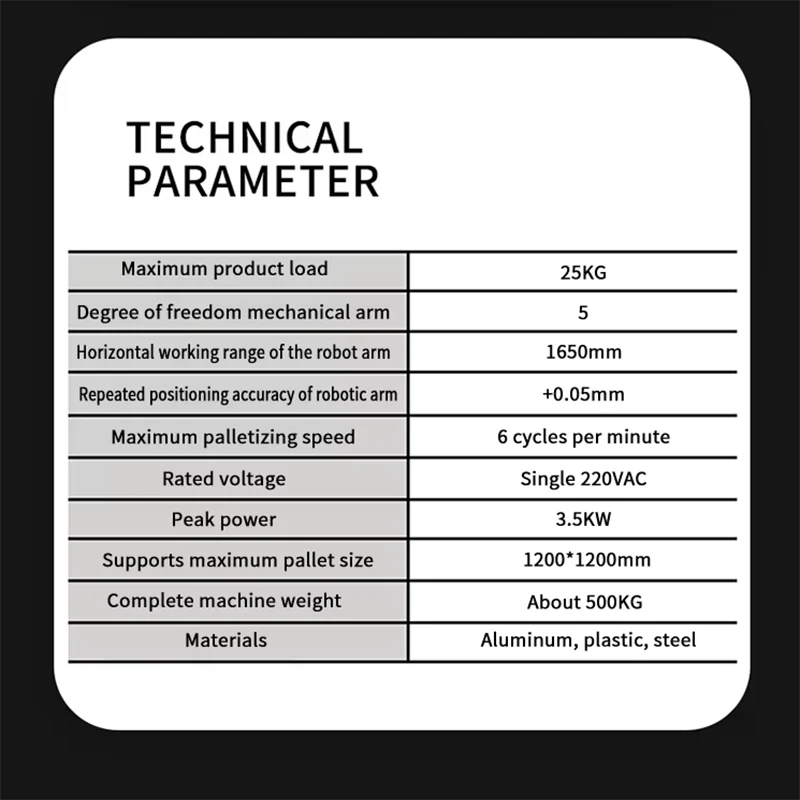

- Speed and precision of large-scale fully automatic collaborative robots: With fast movement speed, they can complete a large number of repetitive tasks in a short time, and have high positioning accuracy, which can ensure the stability of product quality and reduce the defective rate.

- Continuous operation: They can work 24 hours a day without rest, which greatly improves production efficiency and can meet the needs of large-scale production.

自动搬运纸箱码垛机单臂码垛机1.结构简单,操作简单灵活,结构耐用,故障率低2.占...

2025-04-28

As a manufacturer of fully automatic org...

2025-06-29

The 15 - kilogram canned goods vertical ...

2025-06-29

The 50-kg intelligent control carton col...

2025-06-28

The 15 - kilogram rice vertical palletiz...

2025-06-27

2025-06-27

The vertical feed stacker is a key equip...

2025-06-15

Thegantry - type high - level palletizer...

2025-06-14

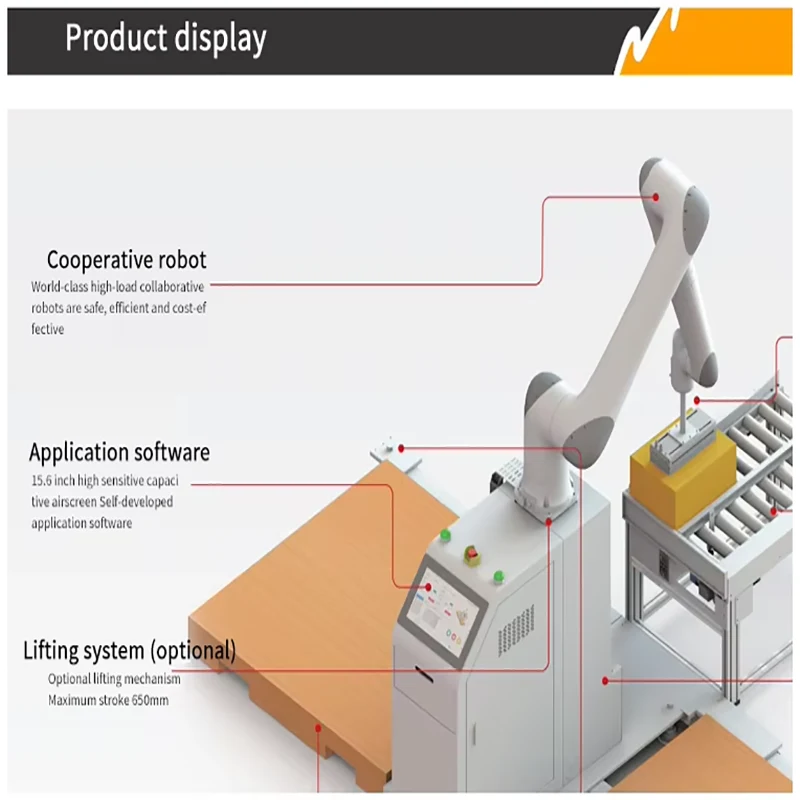

Products Description

Fault diagnosis and maintenance of pet food box collaborative robots: With self-diagnosis function, it can detect faults and alarm in time. At the same time, some robots also support remote monitoring and maintenance, which is convenient for technicians to quickly locate and solve problems and reduce downtime.

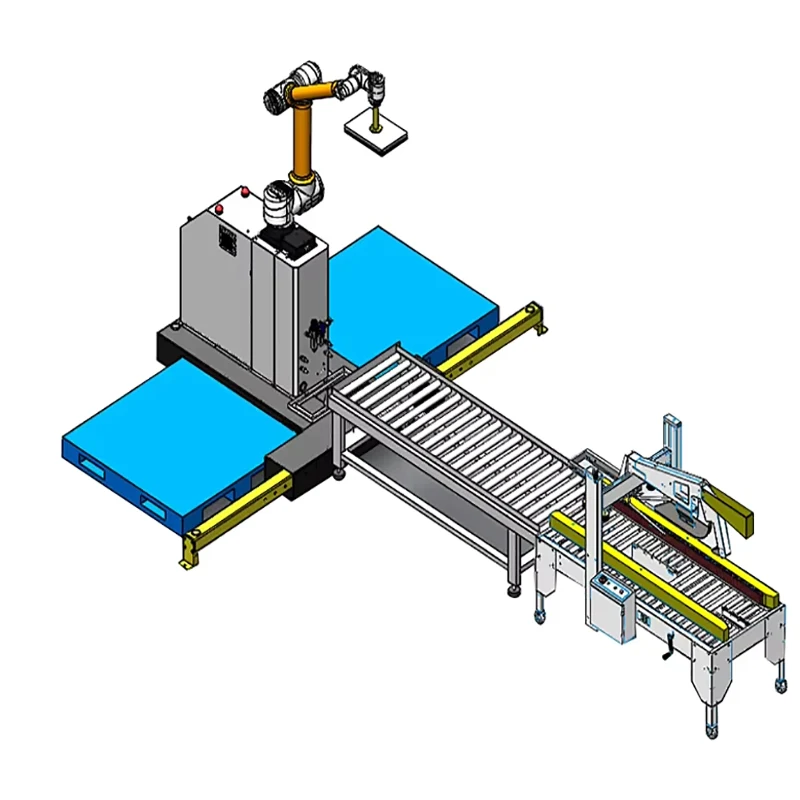

Flexible and universal

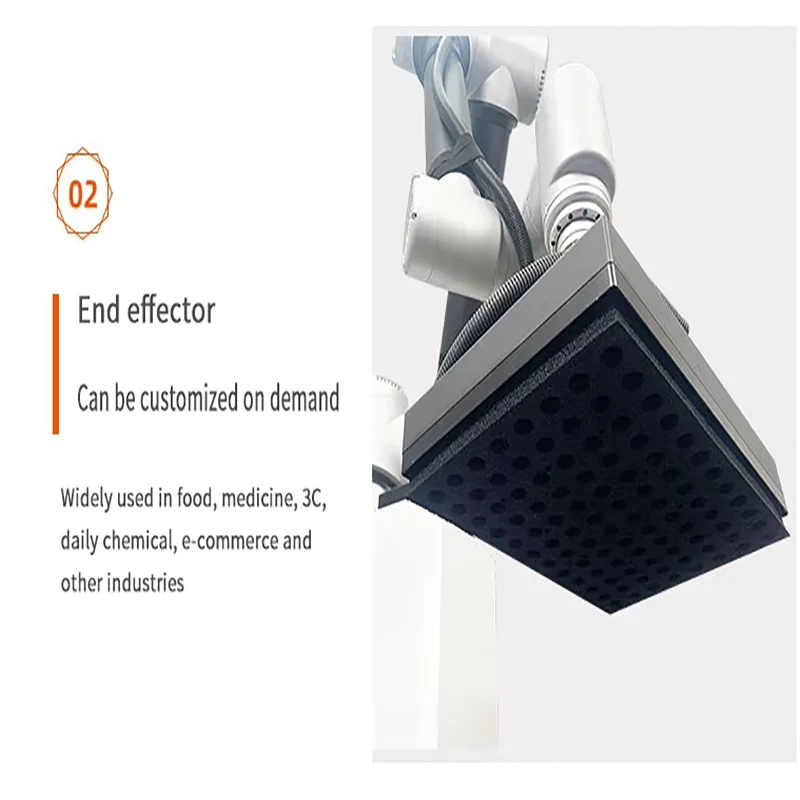

- Multitasking: By replacing different end effectors, such as fixtures, spray guns, welding guns, etc., it can complete a variety of different types of tasks, such as handling, welding, spraying, assembly, etc., to adapt to different production processes and product requirements.

- Programming and deployment: The programming methods are flexible and diverse, and task programming can be quickly completed through teaching, offline programming, etc., and it can be quickly deployed to different production lines to adapt to product upgrades and production layout adjustments.

Data management of pet food box collaborative robots

- Production data recording: Various data can be recorded in real time during the production process, such as production quantity, working hours, fault information, etc., to provide data support for production management and quality control, which helps enterprises to optimize production and make decisions.

- Data analysis and optimization: With the help of big data analysis technology, the robot's operating data can be analyzed to optimize the production process, improve production efficiency, predict equipment failures, and realize intelligent production management.

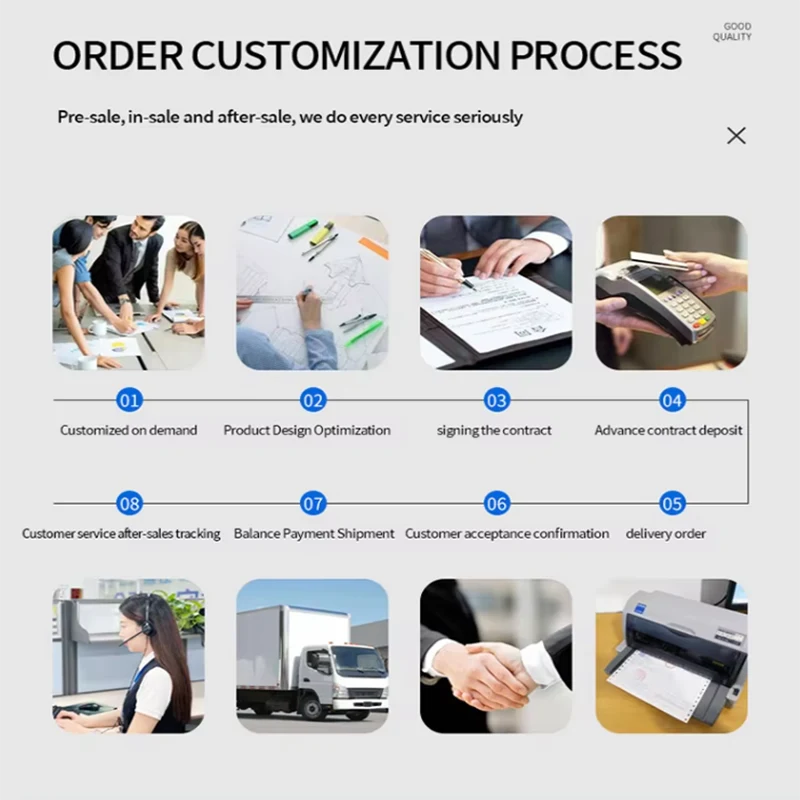

Company Profile

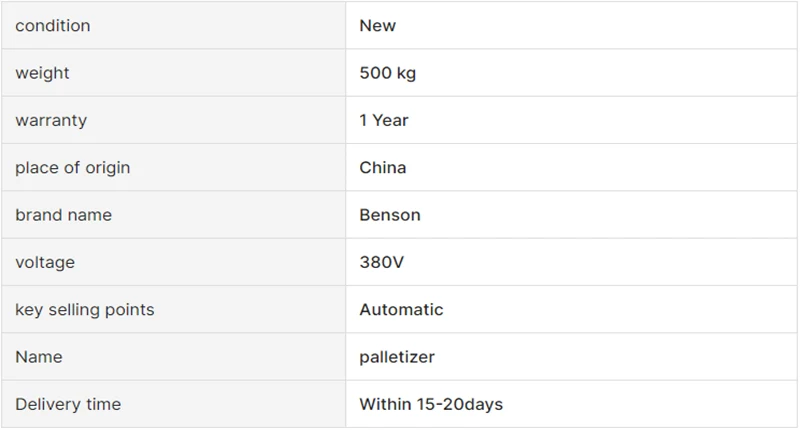

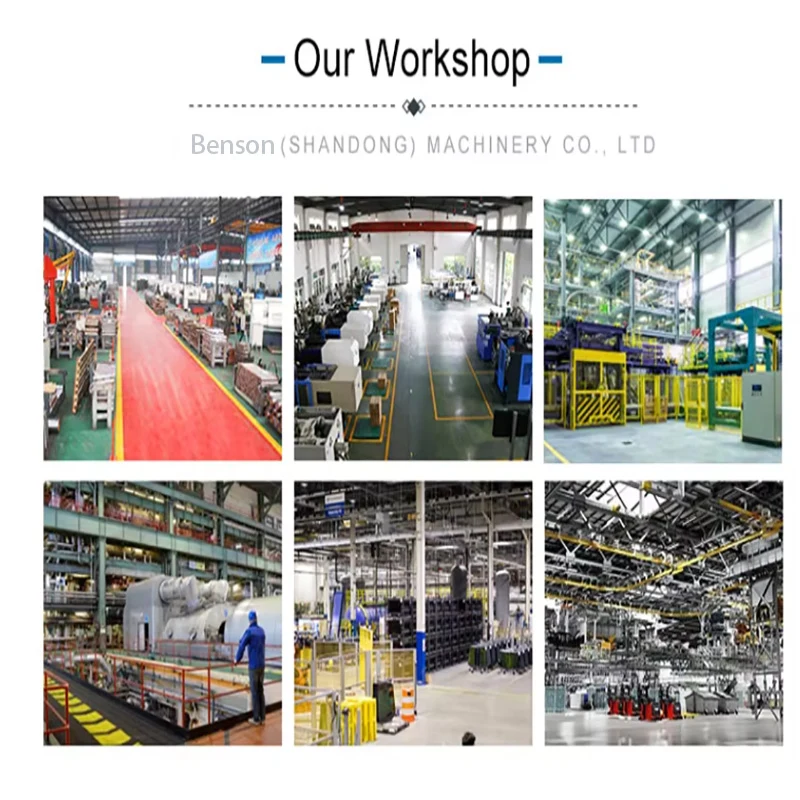

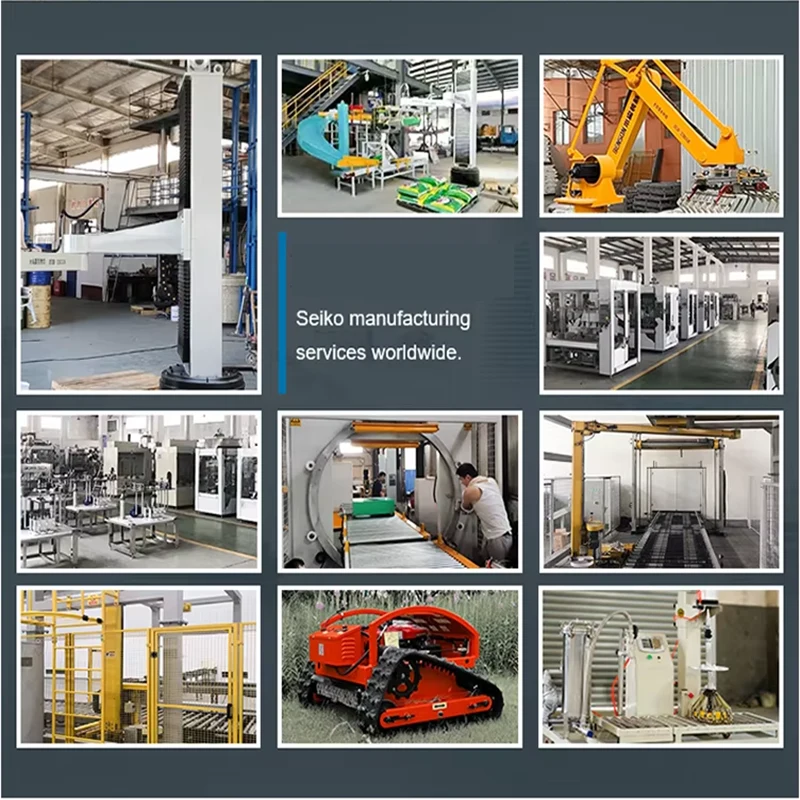

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

产品询价