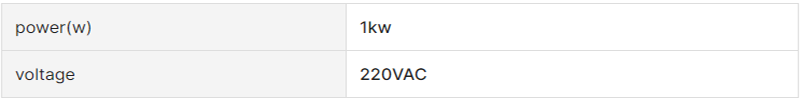

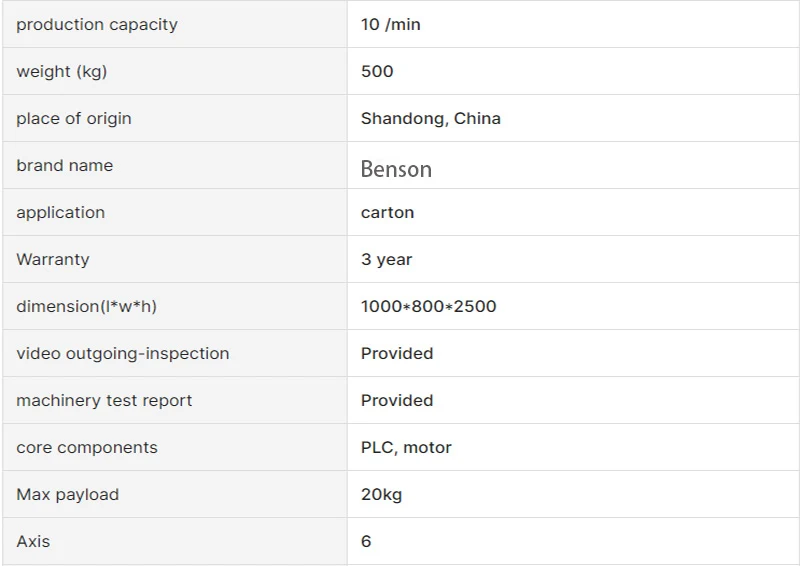

Industry-specific attributes

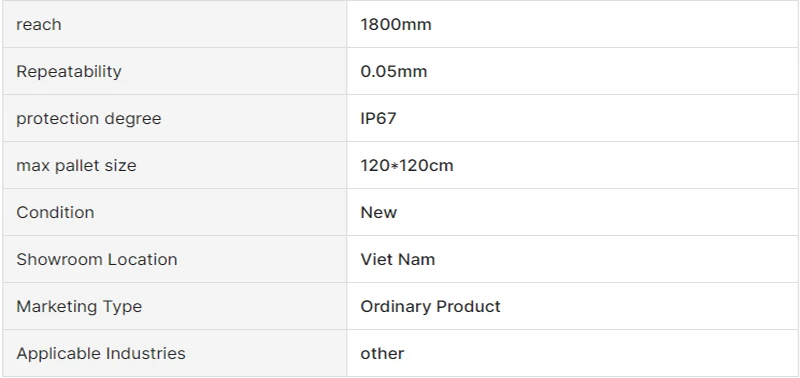

Other attributes

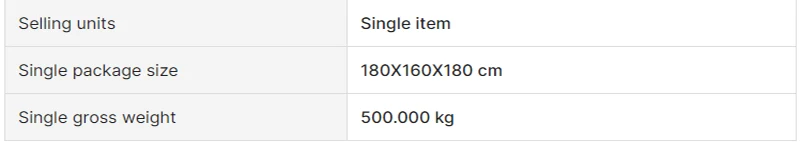

Packaging and delivery

Product descriptions from the supplier

Products Description

1. Safe collaboration: Equipped with a variety of sensors, such as laser radar, visual sensors, force sensors, etc., it can sense the surrounding environment and the approach of people in real time. When encountering obstacles or people entering dangerous areas, it automatically slows down, stops or adjusts its movements to avoid collisions. It can work with workers in the same work area without the need for additional safety isolation facilities.

2. Efficient and accurate: It has a fast running speed and a repeat positioning accuracy of ±[X] mm. It can quickly and accurately grab, carry and place organic fertilizer pallets. It can complete more than [X] loading and unloading actions per hour, which greatly improves the efficiency compared to manual work. The palletizing is neat and standardized, the pallet shape is stable, and the risk of cargo collapse is reduced.

3. Flexible and versatile: The robotic arm has a high degree of freedom and flexible movements. The end effector can be quickly replaced according to different pallet types (such as wooden and plastic pallets) and organic fertilizer packaging forms (bags, barrels), and can adapt to the loading and unloading and palletizing needs of organic fertilizer pallets of various specifications and sizes. It can also flexibly adjust the operation path and method according to the warehouse layout, production line layout and operation process.

4. Intelligent and easy to use: It uses advanced visual recognition system and intelligent algorithm to automatically identify the position and posture of pallets and goods, and plan the optimal operation path. The operation interface is simple and intuitive, supporting various programming methods such as teaching programming and graphical programming. Operators do not need professional programming knowledge and can operate, debug and maintain after simple training. It has fault diagnosis and early warning functions, can detect equipment abnormalities and alarm in time, and is convenient for maintenance personnel to troubleshoot and solve problems.

5. Stable and reliable: The main structure is made of high-strength and wear-resistant materials, and key components are made of high-quality brand products. After rigorous testing and aging tests, it has good anti-interference ability and environmental adaptability. It can operate stably in complex and harsh organic fertilizer production and storage environments such as high temperature, humidity, and dust, reducing equipment failure rate and maintenance costs, and extending service life.

产品询价