Industrial palletizing robots are crucial equipment in the field of industrial automation. Through the collaborative operation of mechanical arms and intelligent control systems, they replace manual labor to complete cargo palletizing tasks, significantly improving production efficiency and logistics turnover speed.In terms of mechanical structure, industrial palletizing robots come in various types:Cartesian robots achieve precise positioning through linear motion along the X, Y, and Z axes,

自动搬运纸箱码垛机单臂码垛机1.结构简单,操作简单灵活,结构耐用,故障率低2.占...

2025-04-28

As a manufacturer of fully automatic org...

2025-06-29

The 15 - kilogram canned goods vertical ...

2025-06-29

The 50-kg intelligent control carton col...

2025-06-28

The 15 - kilogram rice vertical palletiz...

2025-06-27

2025-06-27

The vertical feed stacker is a key equip...

2025-06-15

Thegantry - type high - level palletizer...

2025-06-14

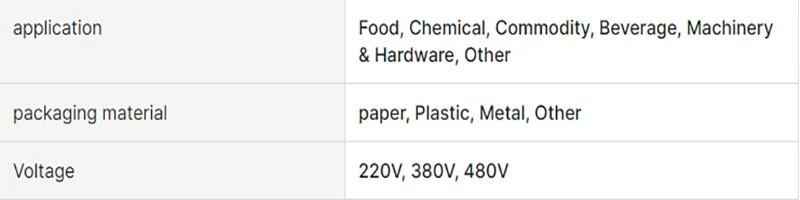

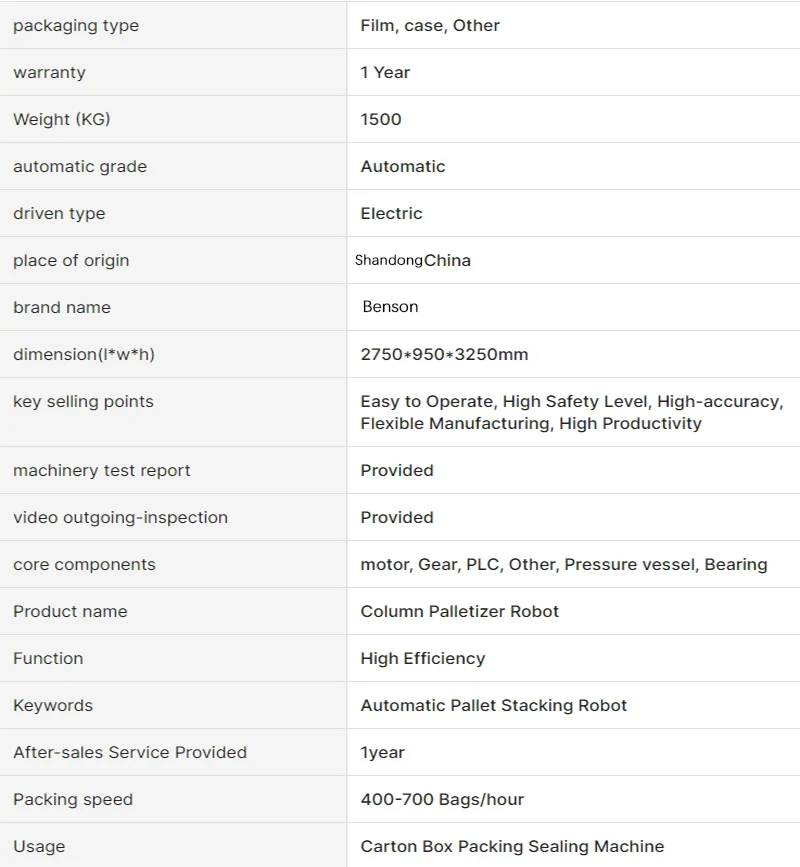

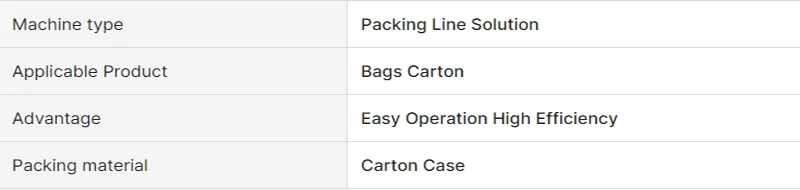

Products Description

Industrial palletizing robot

The core function of industrial palletizing robots is to accurately stack items of various shapes and weights onto pallets or designated positions according to preset patterns through automated operations. Its main components include: the mechanical arm, as the core component responsible for executing grabbing, handling, and stacking operations, with a multi-joint structure that endows it with strong flexibility to adapt to different height and angle requirements; the end-effector, installed at the end of the mechanical arm and customized according to item characteristics, such as grippers, suction cups, or vacuum adsorption devices; the sensing system, used to detect item position, size, weight, and monitor the working environment to ensure operational precision and safety; the control system, which controls the movements of the mechanical arm through program instructions to achieve complex stacking path planning and automated processes; and the base, which provides stable support for the robot, equipped with mobile or fixed structures to balance operational flexibility and safety.

产品询价